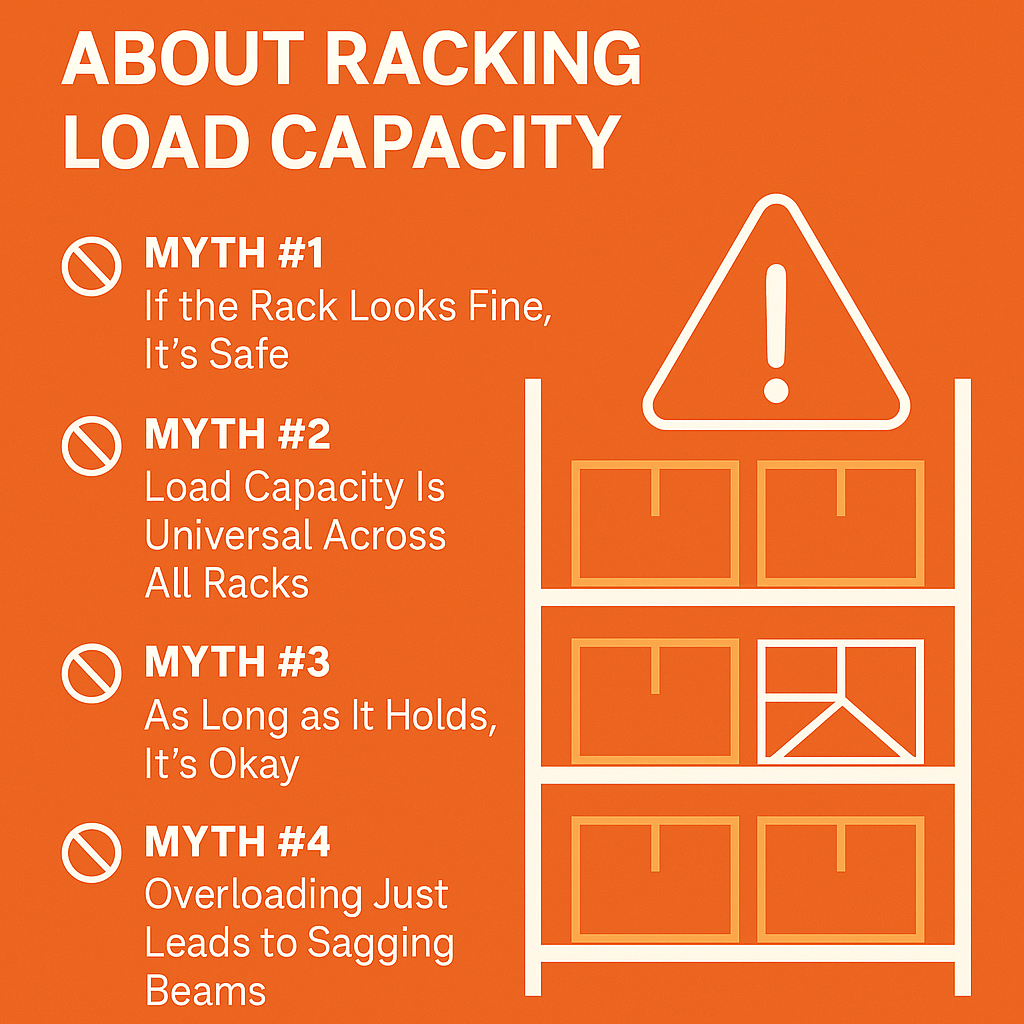

When it comes to warehouse safety and efficiency, one of the most overlooked yet critical aspects is racking load capacity. Despite clear standards and manufacturer guidelines, many businesses fall victim to persistent myths that lead to overloading, structural stress, and even rack collapse. These misunderstandings can cost you thousands in damaged inventory, worker injuries, or even full system failure.

Let’s debunk the most common racking load myths to help protect your people, products, and profits.

Myth #1: If the Rack Looks Fine, It’s Safe

Reality: A racking system may appear stable while internally bearing stress beyond its rated capacity. Visual inspections alone can’t detect hidden damage or the effects of overloading over time.

Key Fact: Always follow manufacturer load limits and schedule routine professional audits—especially after collisions or reconfigurations.

Myth #2: Load Capacity Is Universal Across All Racks

Reality: There is no one-size-fits-all rule. Load capacity varies based on:

- Beam length and profile

- Upright height and thickness

- Number of beam levels

- Anchor bolt installation

Ignoring these variables increases the risk of racking system failure.

Myth #3: As Long as It Holds, It’s Okay

Reality: Just because a rack hasn’t collapsed doesn’t mean it’s safe. Repeated overloading causes structural fatigue, which can lead to sudden, catastrophic failure—especially in seismic-prone or high-traffic environments.

Myth #4: Overloading Just Leads to Sagging Beams

Reality: While beam deflection is a visible sign, the real danger lies in the uprights and connectors. Stress fractures can spread unseen, weakening the structure until it eventually gives way.

Myth #5: Racking Load Capacity Doesn’t Change Over Time

Reality: Age, corrosion, bolt loosening, and repeated forklift collisions can all reduce a rack’s actual load-bearing strength. Even high-quality systems degrade without proper maintenance.

How to Avoid Load Capacity Errors

- Label all racking systems clearly with load ratings

- Train warehouse staff to identify unsafe loading practices

- Never mix and match racking components from different brands

- Schedule regular load tests and inspections

- Invest in racking protection accessories (e.g., upright guards, post protectors)

The Risk of Believing Load Capacity Myths

Failing to understand and enforce load capacity limits can lead to:

- Rack collapse

- Product damage

- Serious injuries or fatalities

- Regulatory violations

- Increased insurance costs

Proper awareness and education are the first steps toward safe warehouse racking.

FAQs: Racking Load Capacity & Safety

Q1: What happens if I exceed racking load capacity by a small margin?

A: Even minor overloading can reduce the life span of your system or create structural fatigue. Repeated overloading increases the risk of sudden failure.

Q2: How can I find out my rack’s actual load limit?

A: Refer to the manufacturer’s specifications. If unavailable, consult a structural engineer or professional racking provider in the UAE.

Q3: Are there load capacity regulations in the UAE?

A: Yes. UAE warehouses must comply with Dubai Civil Defence guidelines and international safety standards (such as SEMA or FEM).

Q4: How often should I inspect racking systems for load-related issues?

A: Visual inspections should be done weekly. Professional safety audits are recommended at least annually—or after any impact or reconfiguration.

Q5: Can using different brands of rack components affect load capacity?

A: Absolutely. Mixing brands or incompatible components can compromise structural integrity and void warranties or certifications.