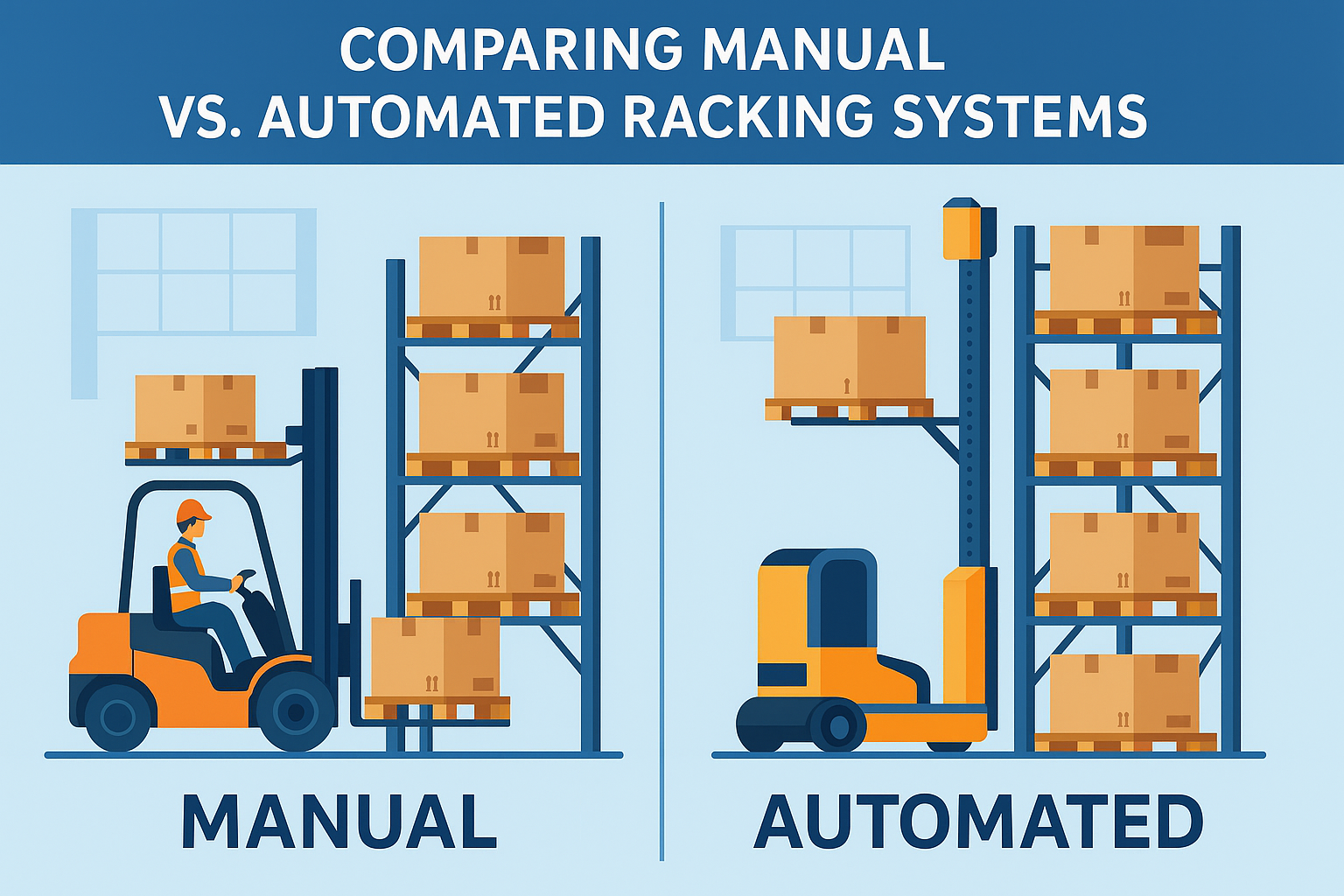

The evolution of warehousing and logistics in 2025 is unmistakable—automation is everywhere. But is an automated racking system the best choice for your business? Or does a manual system offer the flexibility and cost-efficiency your operation needs?

In this article, we dive deep into the Manual vs Automated Racking Systems debate, providing actionable insights to help you make the right investment decision—especially relevant if you’re operating in high-cost logistics zones like Dubai, JAFZA, or Riyadh.

🏗️ What Are Manual and Automated Racking Systems?

✅ Manual Racking Systems

These are traditional storage setups requiring human labor and forklifts for:

- Loading/unloading pallets

- Inventory management

- Replenishment and retrieval

Examples:

- Selective pallet racks

- Drive-in racks

- Cantilever racking

- Push-back racks

🤖 Automated Racking Systems

Automated Storage and Retrieval Systems (AS/RS) use technology like:

- Shuttle systems

- Vertical lift modules (VLMs)

- Stacker cranes

- Warehouse robots

These are integrated with WMS (Warehouse Management Software) for autonomous operations.

⚖️ Side-by-Side Comparison

| Feature | Manual Racking | Automated Racking |

|---|---|---|

| CapEx | Low to Moderate | High upfront investment |

| OpEx (Long-Term Cost) | Higher labor & downtime | Lower long-term cost |

| Storage Density | Moderate | High |

| Labor Dependency | High | Low |

| Space Efficiency | Requires wider aisles | Compact aisles, vertical storage |

| Inventory Accuracy | Manual tracking prone to error | 99%+ with sensors & WMS |

| Scalability | Limited | Highly scalable with software |

| Implementation Time | 1–4 weeks | 3–6 months |

💡 When to Choose Manual Racking

Manual systems still work great in certain use cases:

🔹 Low-to-Medium Throughput

Warehouses that do not move products daily may not justify automation.

🔹 Budget Constraints

Startups or businesses scaling slowly might prefer the lower upfront cost of manual racking.

🔹 Variety of SKUs

If you’re handling odd-sized or fragile items that aren’t automation-friendly.

🏗 Example: Local construction suppliers in Sharjah using drive-in racking for steel products.

🤖 When to Choose Automated Racking

🔸 High Throughput & Fast Order Fulfillment

Automated systems are built for 24/7, high-volume operations—common in eCommerce, FMCG, cold storage, and pharma.

🔸 Labor Shortages

In cities like Dubai where warehouse labor is costly, automation helps minimize headcount.

🔸 Floor Space Is Limited

Urban fulfillment centers and cold storage units benefit from vertical space optimization.

🧊 Case Study: A cold-chain logistics firm in Dubai South increased storage capacity by 40% using shuttle-based AS/RS.

📊 ROI Breakdown

Manual System ROI Timeline:

- Lower initial cost

- ROI in ~12–18 months (slow growth rate)

- Higher recurring labor + maintenance cost

Automated System ROI Timeline:

- High CapEx, but

- ROI in ~18–36 months

- Lower Opex, increased throughput, fewer human errors

🔐 Key Factors to Consider Before Choosing

- Warehouse Size – Larger footprints or multi-level facilities often benefit more from automation.

- Budget vs Long-Term Vision – Can your business absorb upfront cost for long-term savings?

- Order Volume – High daily orders mean automation pays off faster.

- Future Scalability – Automation supports expansion without expanding space.

- System Downtime Risks – Automated systems require expert maintenance.

🔄 Hybrid Systems: The Best of Both Worlds?

Some warehouses in Dubai are adopting hybrid solutions:

- Manual selective racking for slower SKUs

- Shuttle AS/RS or VLMs for fast-moving inventory

This enables cost-effective automation without overhauling your entire infrastructure.

📍 Dubai & GCC Market Perspective

With Expo legacy infrastructure, Dubai is investing in AI-driven logistics and smart warehousing. The trend is clear:

- Amazon UAE, Noon, and Aramex are integrating AS/RS.

- Freezone warehouses are offering automation-ready zones.

- Cold storage firms in JAFZA are investing in VLMs and shuttle racking.

📈 By 2026, over 60% of warehouses in the UAE are expected to incorporate some form of automation.

Final Verdict: Which One Is Right for You?

- Go manual if: you’re just starting, budget-conscious, and have a varied inventory.

- Go automated if: you aim for scale, speed, and long-term ROI with high throughput.

- Go hybrid if: you’re in between, and want the flexibility of both.

✅ Internal Links Suggestions

- How Pallet Flow Racks Improve Efficiency in Dubai Logistics

- Understanding Racking Load Capacities

- Top Warehouse Automation Trends in the UAE

FAQs

1. Can a manual racking system be upgraded later?

Yes. Many manual racking systems can be retrofitted with shuttle carts or automated lifts.

2. What is the lifespan of an automated racking system?

With proper maintenance, AS/RS systems can last 15–20+ years.

3. Do automated racks require skilled operators?

Yes, but minimal. Most systems are software-controlled and need occasional calibration.

4. What is the downtime risk for automation?

With preventive maintenance, downtime is low—but repairs may take longer if systems fail.

5. Is automation viable for SMEs?

Absolutely—especially for niche segments like eCom fulfillment or cold storage where speed and accuracy are vital.