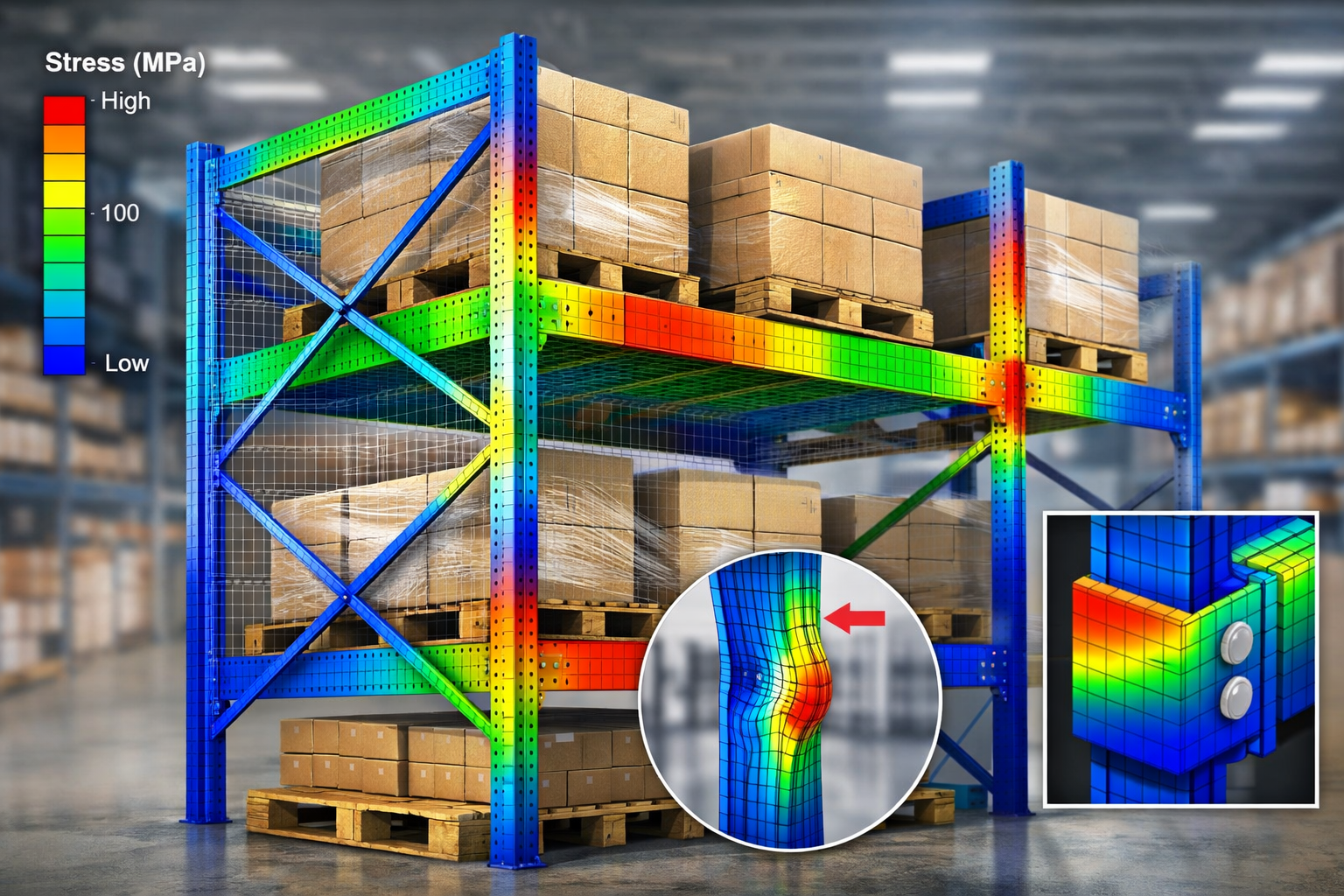

FEA for racking is increasingly used by engineering teams to predict structural failure modes before warehouse storage systems are installed or modified. As storage racks carry heavier loads and operate in more demanding environments, finite element analysis (FEA) provides a data-driven method to assess stress behavior, deformation, and fatigue risk under real-world conditions. This approach supports safer designs and reduces costly failures across logistics, manufacturing, and cold storage facilities.

Why Rack Failure Prediction Matters

Industrial storage racks are subject to multiple forces during their service life. These include static loads from pallets, dynamic impacts from forklifts, seismic forces, and long-term material fatigue. Failure to anticipate these stresses can lead to:

- Progressive deformation of uprights and beams

- Connection failures at joints and anchors

- Local buckling under uneven loading

- Sudden collapse due to cumulative stress

Industry safety investigations have shown that many rack failures originate from design-stage assumptions rather than operational misuse. This has increased reliance on simulation-based validation methods.

How FEA for Racking Works

Understanding Finite Element Analysis in Rack Design

Finite element analysis divides a rack structure into thousands of small elements, allowing engineers to calculate how forces distribute across each component. By applying realistic load cases, FEA reveals weak points that traditional calculations may overlook.

Key Inputs Used in Rack Simulations

Typical FEA models for racking systems include:

- Material properties such as yield strength and elasticity

- Geometric details of beams, uprights, and bracing

- Load scenarios, including asymmetric and dynamic loads

- Boundary conditions like floor anchoring and wall restraints

Engineering software then solves these models to produce stress, strain, and displacement results.

Common Rack Failure Modes Identified Through Simulation

Stress Concentration at Connections

FEA frequently highlights excessive stress at beam-to-upright connectors. These areas are vulnerable to fatigue cracking, especially under repetitive loading cycles.

Buckling of Uprights

Slender uprights may buckle under compressive loads even when overall weight limits appear acceptable. Simulation helps determine critical buckling loads with greater accuracy.

Excessive Deflection

While not always leading to immediate collapse, excessive beam deflection can compromise pallet stability and long-term rack integrity.

Advantages of Using FEA for Racking Systems

Applying FEA during design and evaluation offers several measurable benefits:

- Early detection of structural weaknesses

- Reduced reliance on physical prototyping

- Improved compliance with international rack design standards

- Enhanced safety margins without excessive material use

According to engineering research published in structural mechanics journals, simulation-based validation significantly improves design reliability when combined with physical testing.

Integration with Industry Standards

FEA results are often aligned with standards such as EN 15512, FEM 10.2.02, and RMI specifications. While these standards provide baseline formulas, simulation adds a deeper understanding of real-world behavior, particularly for customized or high-load systems.

In Summary: What This Means for Engineering Teams

Finite element analysis has moved from optional validation to a core engineering tool in rack system design. By using FEA for racking, teams gain clearer insight into failure risks, improve safety outcomes, and make informed design decisions that reflect actual operating conditions rather than assumptions.

FAQs

FEA for racking refers to the use of finite element analysis to simulate how storage racks respond to loads, impacts, and environmental forces. It helps engineers evaluate stress distribution, deformation, and potential failure points before installation or modification.

Finite element analysis identifies hidden structural weaknesses that standard calculations may miss. By modeling real load conditions, it improves prediction accuracy and supports safer rack designs that reduce collapse and long-term fatigue risks.

Yes. FEA allows engineers to simulate extreme and uneven loading scenarios during the design phase. This helps identify failure modes early, enabling design changes before racks are manufactured or installed.

FEA does not fully replace physical testing but complements it. Simulation reduces the number of prototypes required and focuses physical testing on the most critical stress areas identified through analysis.

Industries with high load density or strict safety requirements benefit most, including logistics, cold storage, manufacturing, and automated warehousing. These environments demand precise structural validation to prevent operational disruptions.