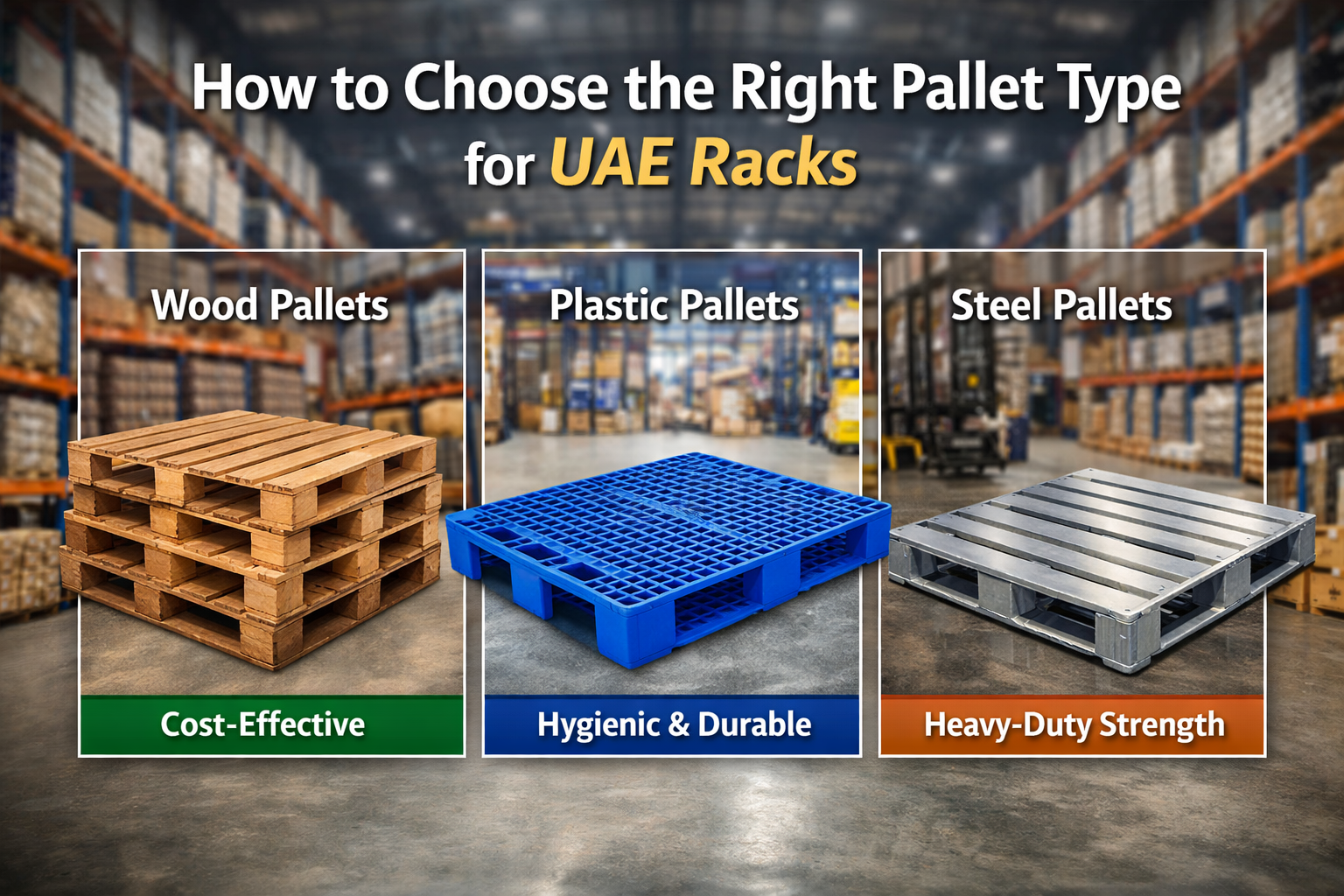

Walk into any warehouse in Dubai, Abu Dhabi, or Sharjah, and you will notice one common element: pallets. They quietly keep goods secure, organised, and moving efficiently. Yet choosing the right pallet type can make or break warehouse operations, especially when selecting pallets for racking in the UAE.

With high temperatures, humidity, and fast-moving supply chains, pallet choice matters more than ever. So which material is the right fit: wood, plastic, or steel? Here is a simple breakdown.

Wood Pallets: Affordable and Widely Used

Wood pallets remain the most common option across warehouses.

Pros

- Cost-effective and suitable for large quantities

- Easy to repair instead of fully replacing

- Strong load capacity for stacking applications

Cons

- Absorbs moisture and may warp in humid environments

- Nails and splinters can damage products

- Not suitable for high hygiene standards such as food or pharmaceuticals

Best For

- General warehousing

- Manufacturing

- Low regulatory storage environments

Plastic Pallets: Hygienic and Durable

Plastic pallets are rapidly gaining popularity across UAE industries, especially for cleaner applications.

Pros

- Moisture-proof and stable in UAE heat

- Lightweight and easier to handle

- Long lifespan and resistant to chemicals

- Ideal for export since no fumigation is required

Cons

- Higher upfront cost than wood

- Cracks usually mean replacement, not repair

- Not optimal for extremely heavy loads

Best For

- Food and FMCG

- Pharmaceuticals and cosmetics

- Cold chain and export logistics

Steel Pallets: Built for Strength

Steel pallets are engineered for high-demand environments where durability cannot be compromised.

Pros

- Exceptional strength for heavy or bulky loads

- Fire and heat resistant

- Suitable for automated high-bay systems

Cons

- Highest cost

- Heavy weight requires machinery for handling

- Overbuilt for lightweight products

Best For

- Industrial and automotive sectors

- Long-term static storage

- Freezer and heavy-duty environments

Quick Comparison Table

| Pallet Type | Cost | Durability | Hygiene | Best For |

|---|---|---|---|---|

| Wood | Low | Moderate | Low | General storage |

| Plastic | Medium | High | Very High | Food, pharma, export |

| Steel | High | Very High | High | Heavy industry and long-term use |

Final Recommendation

The best pallet depends on your warehouse needs.

If budget is the priority, choose wood pallets

If cleanliness and compliance matter, choose plastic pallets

If strength and longevity are essential, choose steel pallets

The most important rule is to confirm pallet compatibility with your racking system and storage loads. A wrong pallet choice can damage racks, slow productivity, or create safety hazards.

Frequently Asked Questions

Steel pallets last the longest, followed by plastic. Wood wears faster but is more affordable to buy in volume.

Yes, but they may absorb moisture and weaken. Plastic pallets are more reliable in cold environments.

Yes. They do not require fumigation or ISPM-15 certification.

No. Pallet dimensions, design, and load ratings must match the rack specifications.

Heat can dry out wood or slightly soften some plastics if left outdoors. Steel is least affected.