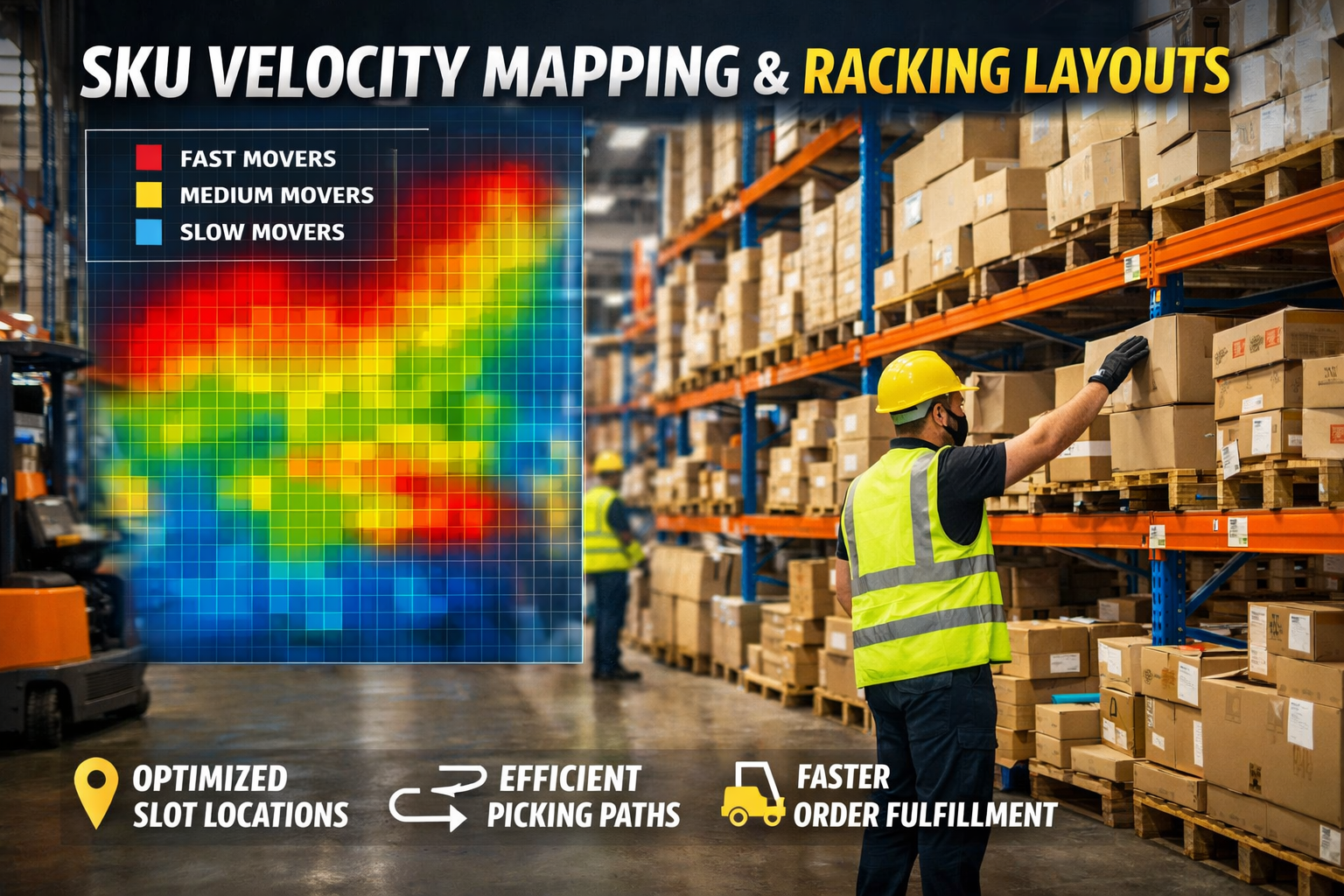

SKU velocity mapping is becoming a critical tool in modern warehouse design. By analyzing how frequently each stock keeping unit (SKU) moves through a facility, operations teams can make informed decisions about racking layouts, slotting strategies, and picking paths. This data-driven approach helps reduce travel time, improve order accuracy, and support faster fulfillment in distribution centers.

As supply chains face rising demand for speed and accuracy, companies are turning to warehouse analytics to optimize space and labor. SKU velocity mapping plays a central role in that transformation.

What Is SKU Velocity Mapping?

SKU velocity mapping refers to the process of measuring how often individual products are picked, replenished, or moved within a warehouse over a specific period. The goal is to identify:

- Fast movers – items picked frequently

- Medium movers – items with moderate demand

- Slow movers – items with infrequent activity

Warehouse management systems (WMS) and inventory analytics tools typically generate this data using order history, seasonal trends, and real-time movement records.

By visualizing SKU activity levels, warehouse planners can assign products to storage locations that best support efficient operations.

Why SKU Velocity Mapping Matters in Rack Design

Traditional racking layouts often prioritize storage density. While space efficiency remains important, modern distribution operations must also consider movement efficiency.

Key Operational Impacts

SKU velocity mapping directly influences:

- Travel distance for pickers

- Congestion in high-traffic aisles

- Replenishment frequency

- Ergonomic safety

According to supply chain research from organizations such as the Warehousing Education and Research Council (WERC), labor travel can account for more than half of total picking time. Reducing unnecessary movement through better slotting can therefore deliver measurable productivity gains.

How SKU Velocity Mapping Shapes Racking Layouts

SKU Velocity Mapping and Slotting Strategy

A well-executed SKU velocity mapping process guides slotting decisions by aligning product demand with physical storage zones.

Common layout adjustments include:

- Placing fast-moving SKUs in easily accessible, ground-level pick locations

- Assigning medium-velocity SKUs to mid-tier rack positions

- Storing slow-moving SKUs in higher or more distant rack bays

This structured placement helps balance labor efficiency with space utilization.

Designing Picking Paths Around Velocity Zones

Once SKUs are grouped by velocity, warehouse designers can create picking paths that minimize cross-traffic and backtracking.

Best practices include:

- Establishing fast-pick zones near packing and shipping areas

- Using batch picking for clusters of high-velocity items

- Separating replenishment routes from active picking aisles

These layout decisions reduce bottlenecks, especially during peak order periods.

Supporting Dynamic Re-Slotting

SKU velocity is not static. Seasonal demand shifts, promotions, and product launches can all change movement patterns.

Warehouses that regularly update velocity data can:

- Re-slot products before peak seasons

- Adjust rack assignments for new fast movers

- Avoid overloading prime pick locations

Periodic reviews ensure the racking layout continues to match real operational needs.

Technology Behind SKU Velocity Mapping

Modern velocity mapping relies on integrated data systems.

Common Data Sources

- Warehouse management systems (WMS)

- Order history databases

- Barcode and RFID tracking systems

- Labor management tools

Analytics platforms convert this data into heat maps, ranking lists, and zone classifications. These visual tools make it easier for planners to translate data into physical layout changes.

Balancing Velocity With Storage Density

While velocity-based slotting improves speed, warehouses must also maintain storage efficiency.

Planners often use a hybrid approach:

- High-density storage (such as pallet racking or deep-lane systems) for slow movers

- Accessible, selective racking for fast movers

- Flexible shelving or carton flow systems for high-turnover items

This balance ensures that space savings do not come at the cost of operational delays.

Operational Benefits of Velocity-Based Racking Layouts

Facilities that apply SKU velocity mapping to racking design often report improvements in:

- Order picking speed

- Labor productivity

- Inventory accuracy

- Worker safety

Shorter travel distances and better-organized pick zones also reduce fatigue and support more consistent performance during high-volume periods.

Key Takeaways

- SKU velocity mapping identifies how frequently each product moves through a warehouse

- Fast movers should be stored in easily accessible rack locations

- Velocity-based slotting reduces picker travel time and aisle congestion

- Regular data reviews are necessary to keep layouts aligned with demand

- Effective racking design balances movement efficiency with storage density

FAQs

SKU velocity mapping is the process of analyzing how often each product is picked or moved within a warehouse. Operations teams use this data to classify items as fast, medium, or slow movers. These classifications guide slotting decisions and help improve racking layouts, picking efficiency, and overall workflow.

By placing fast-moving items closer to packing and shipping areas, warehouses reduce the distance pickers must travel. This lowers picking time, minimizes congestion, and improves productivity. Organized velocity zones also support smoother picking paths and fewer delays during peak demand periods.

Many operations review SKU velocity quarterly, while high-volume or seasonal facilities may analyze it monthly. Regular updates help warehouses adjust to demand changes, new product introductions, and shifting order patterns. Frequent reviews ensure racking layouts continue to support efficient picking and replenishment.

Yes. Proper placement of fast-moving items at accessible heights reduces excessive reaching, bending, and lifting. Clear velocity-based zones also lower congestion in busy aisles. These factors contribute to safer working conditions and help reduce the risk of strain or collision incidents.

Warehouse management systems, barcode scanners, RFID tracking, and order history databases all contribute to velocity analysis. These systems record product movement and picking frequency. Analytics tools then convert the data into reports or visual maps that planners use to design efficient racking layouts.