Warehouse throughput metrics play a critical role in shaping how storage systems are designed and selected. These metrics measure how efficiently goods move through a facility, from receiving to dispatch. For warehouse managers and finance leaders, understanding throughput data helps align racking investments with operational demand, cost control, and long-term scalability. As supply chains face tighter margins and higher service expectations, data-led racking decisions are becoming essential rather than optional.

Understanding Warehouse Throughput Metrics

Warehouse throughput metrics quantify how much inventory a facility processes within a specific timeframe. Common measurements include units per hour, pallets per shift, and order lines per day. These indicators provide a clear picture of operational capacity and flow efficiency.

When reviewed consistently, throughput data highlights whether existing racking systems support or restrict movement, picking speed, and replenishment cycles.

Key Throughput KPIs to Monitor

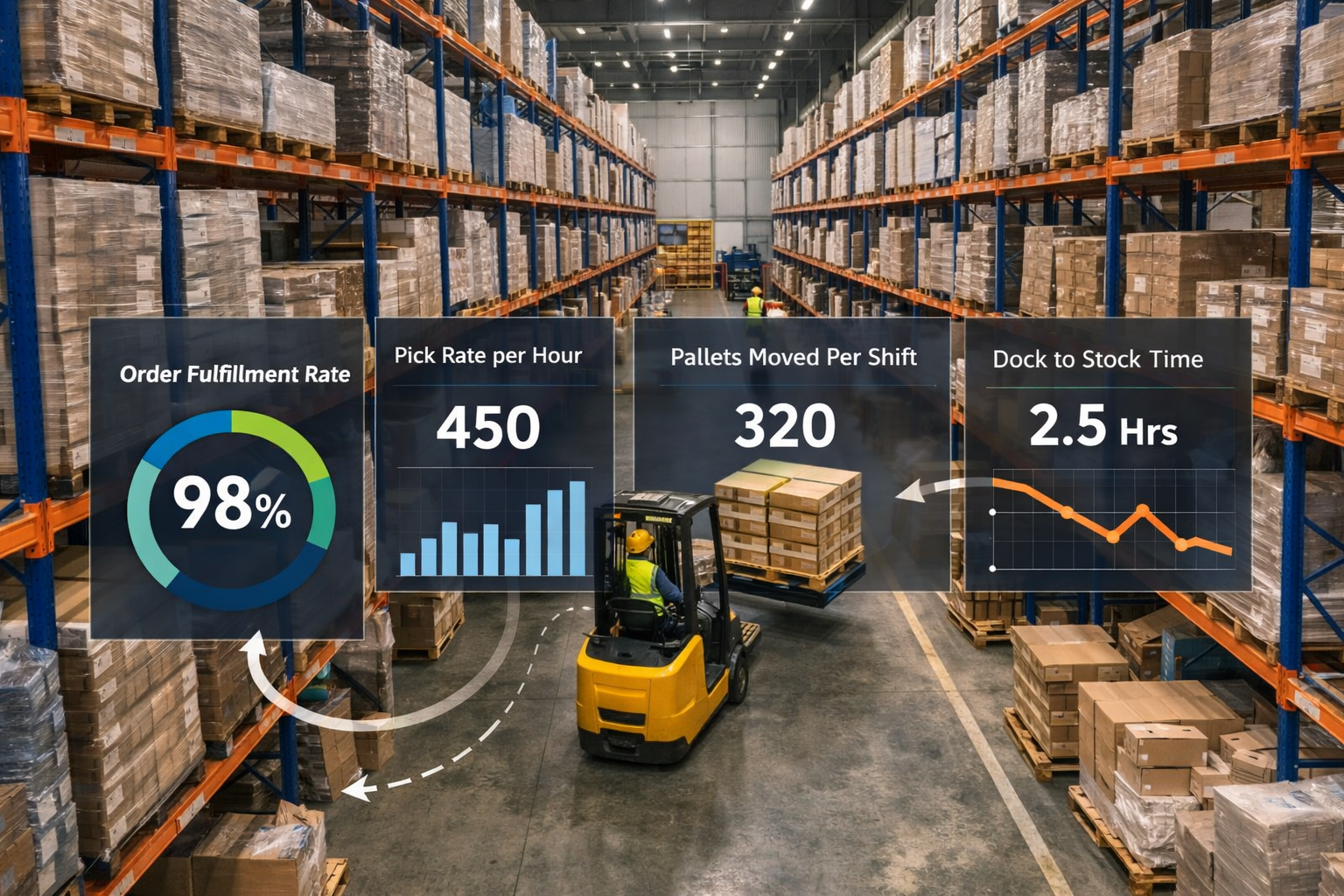

Several KPIs are widely used to evaluate warehouse performance:

- Order fulfillment rate

- Pick lines per hour

- Pallet movements per shift

- Dock-to-stock time

According to supply chain research published by the Council of Supply Chain Management Professionals (CSCMP), facilities that actively track throughput KPIs are better positioned to optimize layout and storage density without sacrificing speed.

How Warehouse Throughput Metrics Shape Racking Selection

Racking Systems Must Match Flow Intensity

Warehouse throughput metrics directly influence the choice between selective racking, drive-in systems, push-back racks, or automated solutions. High-throughput operations typically require faster access and minimal handling steps.

For example, facilities with rapid order turnover benefit from racking that supports:

- Direct pallet access

- Shorter travel paths

- Higher pick-face availability

Lower-throughput warehouses, by contrast, may prioritize storage density over speed.

Aligning Racking Design With Efficiency Data

Efficiency data reveals where congestion, delays, or bottlenecks occur. If throughput metrics show slow picking rates or extended replenishment times, the racking layout may be contributing to the problem.

Adjustments often include:

- Reducing aisle width where feasible

- Reconfiguring pick locations

- Introducing flow-based racking for fast-moving SKUs

These changes are most effective when driven by measured performance, not assumptions.

Financial Implications of Throughput-Based Racking Decisions

From a finance perspective, warehouse throughput metrics support more accurate capital planning. Racking investments represent long-term assets, and mismatched systems can inflate labor costs or limit growth.

Data-backed racking decisions help organizations:

- Improve return on invested capital

- Reduce handling and labor expenses

- Delay costly warehouse expansions

A report by Deloitte on supply chain productivity notes that data-informed infrastructure choices consistently outperform reactive upgrades.

Using Throughput Metrics for Future-Proofing

Throughput trends also indicate how demand is evolving. Seasonal spikes, SKU proliferation, or faster delivery expectations can strain existing systems.

By analyzing throughput patterns over time, warehouse planners can select racking that adapts to:

- Volume fluctuations

- Changing order profiles

- Automation integration

This approach reduces the risk of premature obsolescence.

Key Takeaways

Warehouse throughput metrics provide more than operational insight. They guide smarter racking choices that balance speed, cost, and capacity. When throughput data informs storage design, warehouses operate more efficiently and remain financially resilient in a changing supply chain environment.

FAQs

Warehouse throughput metrics measure how quickly goods move through a facility over a defined period. They typically track units, pallets, or order lines processed per hour or per day, helping managers evaluate operational efficiency and capacity utilization.

Throughput metrics reveal how storage systems impact picking speed, movement flow, and congestion. Using this data ensures racking systems support actual demand levels rather than relying on assumptions or generic layouts.

Common KPIs include pick rate per hour, pallet movements per shift, order fulfillment speed, and dock-to-stock time. Together, these indicators provide a comprehensive view of warehouse performance.

Higher throughput efficiency often reduces labor hours, handling errors, and equipment wear. Racking systems aligned with throughput data help control operating costs and improve long-term return on investment.

Yes. Analyzing throughput trends over time helps anticipate growth, seasonal demand changes, and automation readiness. This allows warehouses to select adaptable racking systems that remain effective as business needs evolve.