As warehouse owners and logistics managers in the UAE know, investing in racking is a long-term decision that directly impacts safety, efficiency, and ROI. Yet many businesses choose a supplier based solely on price, risking poor-quality installations that can lead to system failure or non-compliance with UAE safety standards.

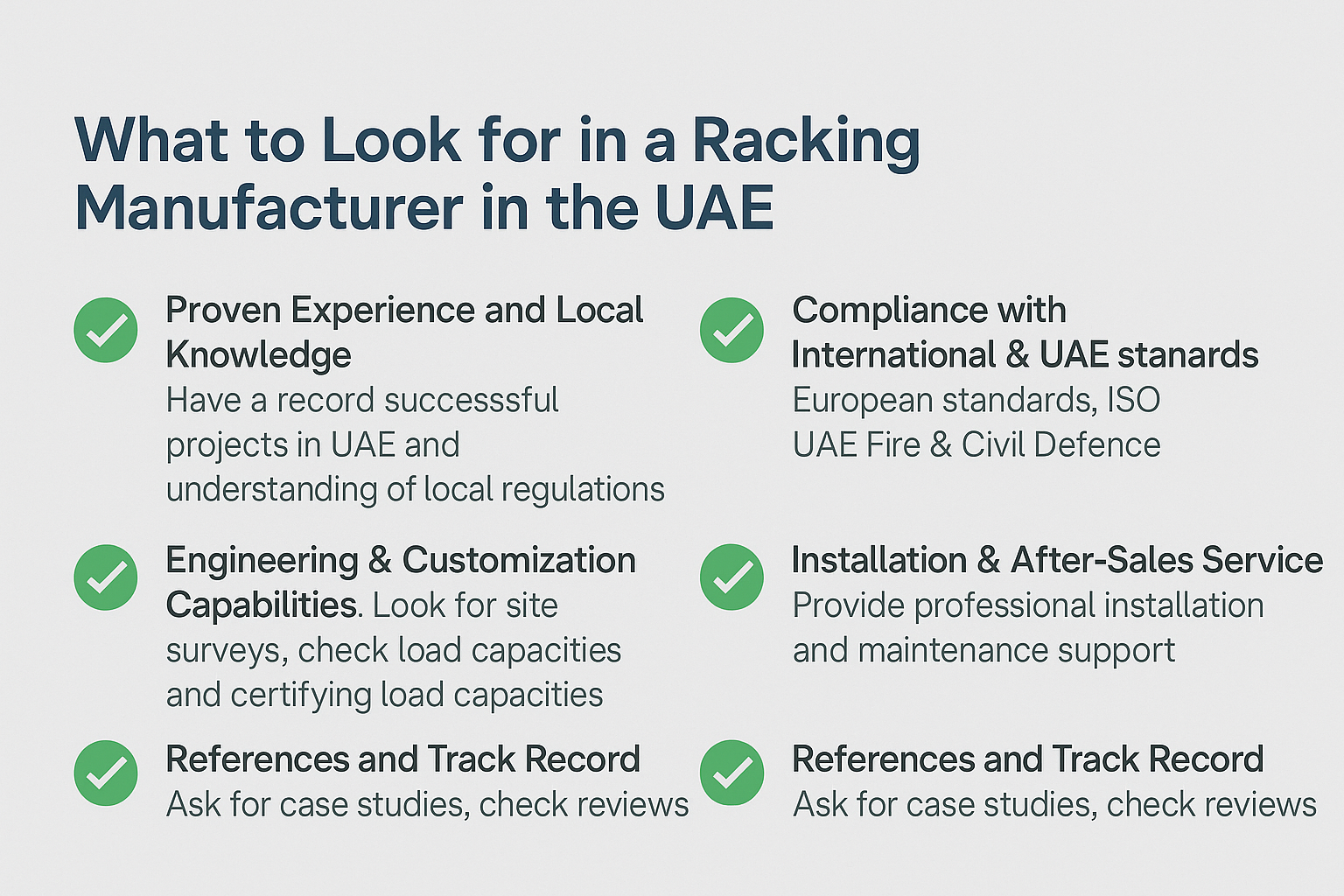

Here’s what you need to look for when selecting racking manufacturers in Dubai or anywhere in the UAE:

1. Proven Experience and Local Knowledge

Your racking partner should have years of successful projects in the UAE, understanding local regulations, climate challenges, and supply chain needs. A racking manufacturer with Middle East expertise can provide solutions that stand up to high temperatures and region-specific safety codes.

2. Compliance with International & UAE Standards

Always confirm that your vendor’s racking systems comply with:

- European standards (FEM, EN)

- ISO certifications

- UAE Fire & Civil Defence codes

This ensures the racks are safe for your employees and assets.

3. Engineering & Customization Capabilities

A reliable racking manufacturer in Dubai should offer custom design services for unique warehouse layouts. Look for vendors who:

- Conduct site surveys

- Provide CAD drawings

- Offer engineering certification for load capacities

4. Quality of Materials & Manufacturing

Not all steel is created equal. Ask your supplier about the grade and thickness of steel used. Inquire about corrosion protection options such as powder coating or galvanization especially important in coastal or humid areas of the UAE.

5. Installation & After-Sales Service

Choose a manufacturer that provides:

- Professional installation teams

- Clear installation manuals

- After-sales inspections

- Prompt repairs and spare parts availability

6. References and Track Record

Ask for case studies or site visits to previous projects. Speaking with existing clients helps verify the supplier’s reliability, adherence to deadlines, and customer service quality.

7. Safety Training & Documentation

The best suppliers train your staff in safe racking use, provide detailed load capacity charts, and issue maintenance guidelines key to preventing accidents and avoiding downtime.

Why You Shouldn’t Choose a Racking Manufacturer Based on Price Alone

Opting for the cheapest option often leads to:

- Substandard materials prone to bending or cracking

- Poor welding or assembly quality

- Inadequate engineering leading to rack collapse risks

- Shorter life span and higher replacement costs

When it comes to safety-critical infrastructure like racking, investing in a quality racking supplier in Dubai pays off through better durability, lower maintenance, and improved warehouse efficiency.

FAQs: Choosing a Racking Manufacturer in the UAE

Q1. How do I know if a racking manufacturer is certified in the UAE?

A: Ask for compliance certificates (ISO, FEM), Fire & Civil Defence approvals, and proof of local authority registration.

Q2. Is it better to work with a local or international racking brand?

A: A local manufacturer with proven UAE experience is often best they can adapt faster to regulations, site challenges, and logistics needs.

Q3. Do racking manufacturers in Dubai offer warranties?

A: Reputable vendors typically offer 1-5 year warranties on structural components, covering defects and premature failures.

Q4. What’s the typical lead time for new racking orders in the UAE?

A: Depending on customization, standard lead times range from 2-6 weeks. Complex projects with engineering approvals can take longer.

Q5. Why is a site visit important before choosing a racking supplier?

A: A site visit helps manufacturers understand your warehouse layout, floor load ratings, and operational workflows, ensuring they design an optimal racking system.