Introduction to Racking Systems

Racking systems are critical components of modern warehouse management, designed to efficiently organize and store a variety of goods. These systems facilitate effective space utilization, allowing businesses to maximize storage capacity while ensuring accessibility to items when needed. Various types of racking systems exist, each tailored to specific storage needs and warehouse configurations.

The most common types include selective racking, which offers easy access to individual pallets; drive-in racking, ideal for high-density storage; and cantilever racking, which is perfect for long or bulky items. Additionally, pallet flow racking allows for first-in, first-out inventory management, enhancing stock rotation. Choosing the right racking system depends on factors such as the nature of the inventory, the layout of the warehouse, and the movement patterns of goods.

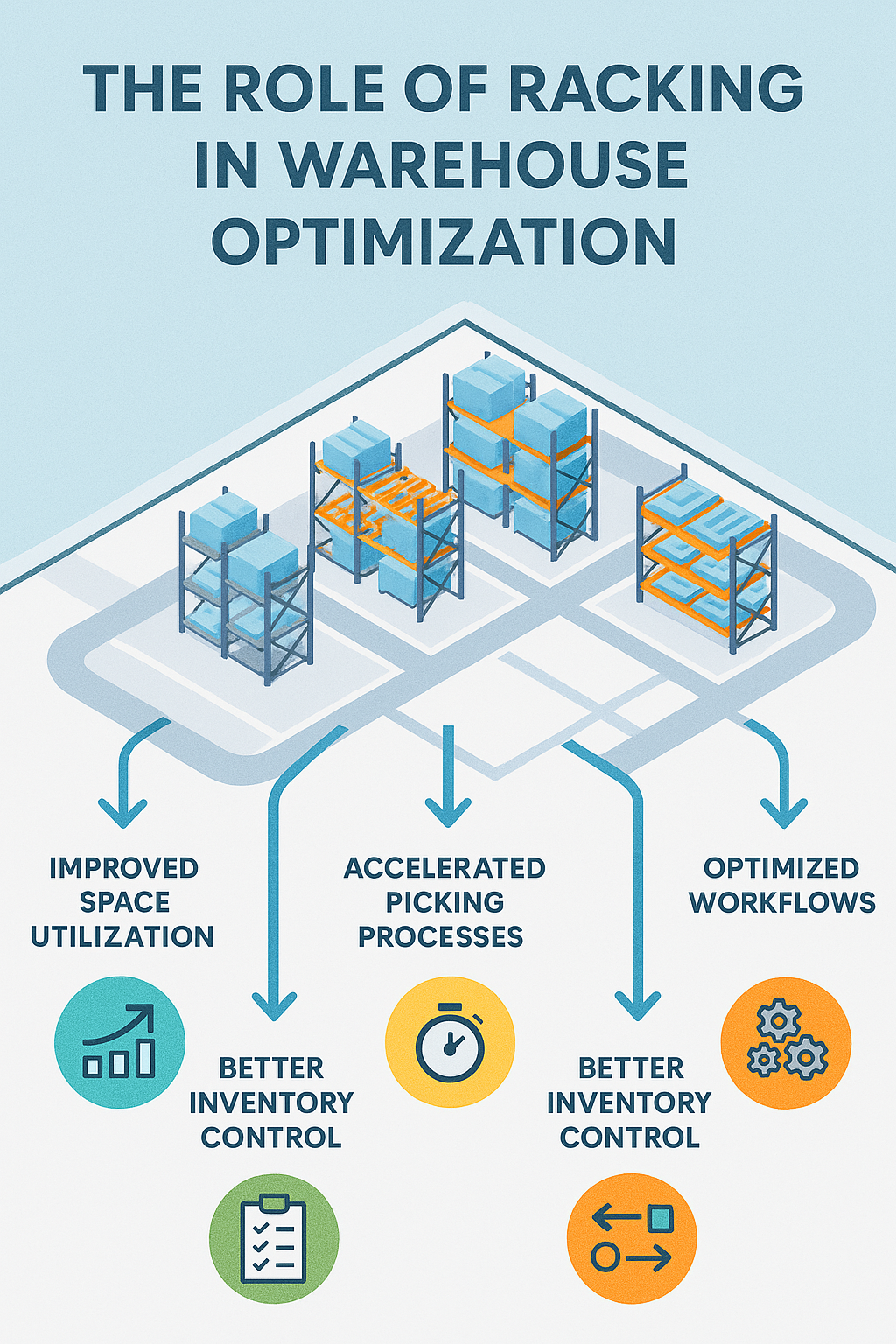

Integrating an appropriate racking system into warehouse operations not only optimizes storage space but also contributes to improved inventory management and retrieval processes. Effective racking strategies can lead to reduced operating costs and enhanced productivity, as they facilitate more efficient use of floor space and streamline the pick-and-pack process. Furthermore, well-designed racking systems can help maintain order and organization, reducing the time workers spend looking for items and minimizing the risk of damage to both goods and personnel.

However, the implementation of racking systems also necessitates a strong focus on safety regulations and audits to ensure compliance and protect employees. Regular racking safety audits assess the integrity and functionality of the systems in place, ultimately minimizing hazards and enhancing warehouse efficiency. As such, understanding racking systems’ roles becomes vital in fostering a safe and productive warehouse environment that meets the demands of today’s logistics and supply chain challenges.

Understanding Racking Safety

Racking safety is a critical component of warehouse operations, as it directly influences the safety of workers and the integrity of stored products. In a warehouse environment, racking systems play a pivotal role in managing inventory effectively. However, poorly maintained or inspected racking structures can pose significant risks. For instance, when racks are not appropriately installed or regularly assessed for wear and tear, they may become unstable, increasing the likelihood of collapse. This instability not only endangers employees who navigate around or underneath these systems but may also lead to catastrophic product loss or damage.

One of the primary hazards associated with racking systems is the potential for forklift accidents. Forklifts are commonly used in warehouses to retrieve and store goods, and improper racking can impede their operations. If pallets are not stacked correctly or if racks are overloaded, there is a risk that the load may fall, causing injuries or fatalities. Additionally, frequent collisions between forklifts and racking structures could occur if visibility is obstructed by improperly organized inventory, further complicating the necessity for racking safety.

Another aspect to consider is structural degradation over time. Racking systems are exposed to various stressors, including the weight of stored goods and environmental conditions. Metal fatigue, rust, and wear can compromise the integrity of these systems, which is why ongoing inspections are essential. Identifying potential issues early can facilitate preventive measures, thus protecting the workforce and maintaining operational efficiency.

In summary, racking safety encompasses multiple facets, from the stability of the storage systems to the operational practices followed in handling materials. Conducting regular safety audits is not merely a compliance issue; it is a fundamental strategy to mitigate hazards, ensuring that the workplace remains a safe environment for all employees while safeguarding valuable inventory.

The Purpose of Racking Safety Audits

Racking safety audits serve a critical role in ensuring the structural integrity and operational efficiency of warehouse environments. The primary purpose of these audits is to identify potential risks associated with racking systems, evaluate compliance with relevant safety regulations, and implement corrective measures to enhance overall safety. A systematic safety audit typically begins with a thorough inspection of the racking systems, focusing on aspects such as load capacities, structural damages, and general wear and tear. This initial step is crucial as it lays the groundwork for understanding the current state of the warehouse infrastructure.

Following the inspection, the next phase of the audit involves a comprehensive evaluation of compliance with safety regulations and industry standards. This evaluation ensures that the racking systems meet established guidelines set forth by governing bodies, such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute). Adhering to these regulations is essential not only for legal compliance but also for safeguarding the lives of employees who navigate these environments daily. Non-compliance can lead to severe consequences, including accidents or injuries, which can have significant ramifications for both personnel and business operations.

Once potential risks and compliance issues have been identified, the audit process shifts to the implementation of corrective measures. This may involve repair or replacement of damaged components, training staff on proper racking practices, or restructuring workflows to minimize hazards. Ensuring that these corrective actions are executed effectively is vital to creating a culture of safety within the warehouse. Ultimately, the continuous monitoring and regular conducting of racking safety audits help maintain optimal efficiency and safety in warehouse operations, significantly reducing the likelihood of accidents and improving overall productivity.

Benefits of Racking Safety Audits

Regular racking safety audits are essential for maintaining a safe and efficient warehouse environment. One significant benefit of these audits is the increased safety they provide for employees. By identifying potential hazards within the racking system, safety audits enable swift corrective measures that can prevent accidents. Ensuring that racks are well-maintained and correctly utilized minimizes the risk of load failures and ultimately protects the workforce from injuries.

Additionally, conducting frequent racking safety audits can have a profound impact on preventing costly accidents. Damages to both personnel and property during incidents such as racking collapses can lead to exorbitant expenses, including medical claims, legal liabilities, and equipment repairs. By investing in regular racking safety evaluations, businesses can significantly reduce the likelihood of such mishaps, ultimately fostering a more cost-effective operational environment.

Enhanced operational efficiency is another crucial advantage of racking safety audits. When racking systems are regularly assessed, it ensures that they are organized and functioning optimally. Efficient racking setups facilitate faster retrieval and storage processes, thereby increasing the overall productivity of warehouse operations. Employees can navigate through the warehouse with ease when the racking is in peak condition, allowing for a streamlined workflow.

Finally, racking safety audits play a vital role in improving inventory management. These assessments allow for a systematic evaluation of inventory storage practices, ensuring that stock is stored in a manner that maximizes space while minimizing the risk of damage or loss. Maintaining a clear and well-audited racking system promotes accurate inventory control, making it easier to track stock levels and fulfill customer orders efficiently.

Regulatory Compliance and Standards

In the realm of warehouse operations, ensuring regulatory compliance is paramount for maintaining safety and efficiency. The Occupational Safety and Health Administration (OSHA) outlines specific regulations that pertain to racking systems, which must be adhered to in order to ensure the safety of employees and the integrity of operations. Compliance with these safety standards is not a mere suggestion, but a legal obligation for organizations that utilize racking systems in their warehouses.

OSHA’s guidelines address various aspects of warehouse safety, including the design, installation, and maintenance of racking systems. These regulations are designed to minimize the risks associated with improper racking practices, such as structural failure or accidents during material handling. Regular safety audits play a critical role in helping organizations evaluate their current racking systems against these established guidelines. By conducting thorough audits, businesses can identify potential non-compliance issues before they lead to serious incidents or penalties.

Furthermore, beyond OSHA’s guidelines, there are various industry standards such as those published by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). These standards provide additional benchmarks for safety and performance in racking systems. Organizations that prioritize compliance with these regulations not only safeguard their employees but also enhance their operational efficiency. By fostering a culture of safety through regular audits, businesses can demonstrate their commitment to quality, thereby improving their reputation and trust with customers and stakeholders alike.

In concluding this discussion, it becomes evident that racking safety audits are indispensable for ensuring regulatory compliance. Organizations that regularly conduct these audits are better positioned to understand and adhere to safety standards, ultimately leading to a safer and more optimized warehouse environment.

Racking Safety Audit Best Practices

Conducting effective racking safety audits is crucial for maintaining a safe warehouse environment and optimizing operations. One best practice is to establish a regular audit frequency. Depending on the racking system and warehouse activity levels, audits should generally be conducted at least quarterly. However, facilities with higher risks may benefit from monthly assessments. Consistent audits help to identify potential issues early and ensure ongoing compliance with safety standards.

Involving employees in the audit process can enhance the effectiveness of safety audits. Employees who work with the racking systems regularly are often more attuned to potential hazards and inefficiencies. Therefore, integrating their insights can lead to a more comprehensive evaluation. Training programs can also be implemented to equip staff with the skills necessary to participate actively in racking safety audits, fostering a culture of safety awareness and responsibility.

Using checklists is another invaluable practice for conducting racking safety audits. A detailed checklist can provide a standardized approach to evaluations, ensuring that no critical factors are overlooked. Items on the checklist should include inspections of structural integrity, load capacity markings, and the overall cleanliness of the racking area. This systematic approach not only streamlines the audit process but also simplifies documentation and follow-up procedures.

Documenting findings from each audit is essential for tracking safety improvements and compliance over time. A thorough record can help identify recurring safety issues, which can then be addressed proactively. Additionally, maintaining detailed records can serve as a resource for training and ongoing operational enhancements. Sharing the findings with relevant stakeholders fosters transparency and encourages collaborative efforts towards continuous safety improvements in warehouse racking systems.

Case Studies: Successful Racking Safety Audits

Implementing racking safety audits has proven to be a beneficial practice for numerous warehouses that have faced significant challenges associated with storage safety and efficiency. One notable case study involves a leading distribution center, which experienced an alarming rate of rack collapses due to improper load balancing and outdated equipment. To address these issues, the management decided to perform a comprehensive racking safety audit. This involved assessing the stability and strength of their racking systems and engaging an external consultant to provide expertise. Following the audit, the facility upgraded their racking systems and implemented a rigorous training program for their staff focused on proper loading techniques and safety protocols. Within six months, the incident of rack-related accidents decreased by over 60%, demonstrating the direct correlation between the audit process and improved warehouse safety.

Another example can be found in a regional logistics provider that recognized the need for a racking safety audit when they recorded an uptick in near-miss incidents. The audit revealed that many of their racking systems did not comply with the latest safety standards. As a response, they developed a multi-faceted plan, which included updating their racking configurations, enhancing the layout for better accessibility, and introducing regular safety training sessions for employees. The outcome was a notable increase in operational efficiency, as well as heightened employee awareness regarding safety. Subsequently, the company noted a significant reduction in safety violations.

These case studies illustrate that racking safety audits serve not only to enhance safety standards within warehouses but also improve overall operational performance. The challenges faced prior to the audits underscore the critical nature of regular evaluations and consultations. Businesses that prioritize these safety audits will likely reap the benefits of reduced accident rates and enhanced employee morale, ultimately contributing to more effective warehouse optimization.

Integrating Racking Safety Audits into Warehouse Optimization Strategies

Integrating racking safety audits into warehouse optimization strategies is critical for enhancing both safety and efficiency within storage environments. A robust racking safety audit serves not only as a mechanism for identifying potential hazards but also as a pivotal component in streamlining overall warehouse operations. The interplay between safety and efficiency is vital; when safety protocols are well-established, they contribute to improved operational flow and reduced downtime caused by accidents or equipment failures.

The implementation of regular racking safety audits can uncover deficiencies in storage solutions, thereby optimizing the usage of warehouse space. For instance, by assessing the integrity of racking systems and their compliance with safety standards, warehouses can minimize risks, ensuring that shelving systems support not only the weight of goods but also the operational needs. This proactive approach enables better inventory management, as it fosters confidence in the organization and storage of products, potentially leading to enhanced order fulfillment rates.

Moreover, integrating safety audits into broader optimization strategies promotes a culture of safety within the organization. When employees recognize that their well-being is prioritized through systematic evaluations of racking systems, their productivity typically increases. Engaging workers in safety practices encourages ownership and accountability, which further contributes to a secure work environment and improves morale. Additionally, organizations that emphasize safety within their optimization strategies are likely to see a reduction in insurance costs associated with workplace injuries.

In conclusion, the synergy between racking safety audits and warehouse optimization is essential for fostering a comprehensive approach to operational excellence. By prioritizing safety and efficiency as interconnected elements, businesses can achieve a safer, more productive work environment that contributes to overall organizational success.

Conclusion and Call to Action

In the realm of warehouse optimization, the significance of racking safety audits cannot be overstated. Throughout this blog post, we have examined how systematic audits strengthen the structural integrity of storage systems, enhance employee safety, and ultimately contribute to overall operational efficiency. Racking systems, being a vital part of warehouse logistics, require regular evaluation to ensure compliance with safety standards, effectively minimizing potential risks and maximizing storage capacity.

Regular racking safety audits serve multiple purposes, including the identification of wear and tear, compliance with safety regulations, and assessment of racking configuration concerning the specific needs of the warehouse. Implementing these audits allows warehouse managers to proactively address any issues that may arise, from minor adjustments to major structural repairs. Thus, they not only prevent accidents but also enhance productivity by ensuring that storage operations run smoothly without interruptions caused by safety breaches.

Moreover, involving employees in the audit process fosters a culture of safety and accountability within the workplace. By encouraging staff to participate in regular inspections, companies can benefit from their insights and observations, making the audit process more comprehensive and effective. This collaboration not only empowers the employees but also reinforces the importance of maintaining a safe working environment.

In light of these insights, we encourage warehouse managers and supervisors to evaluate their current racking systems actively. Conducting thorough safety audits should not be viewed merely as a regulatory requirement but as a strategic investment in the safety, efficiency, and profitability of warehouse operations. By prioritizing racking safety audits, you pave the way for a more secure and optimized work environment. Take immediate action and assess your racking systems today to ensure your warehouse operates at its best.