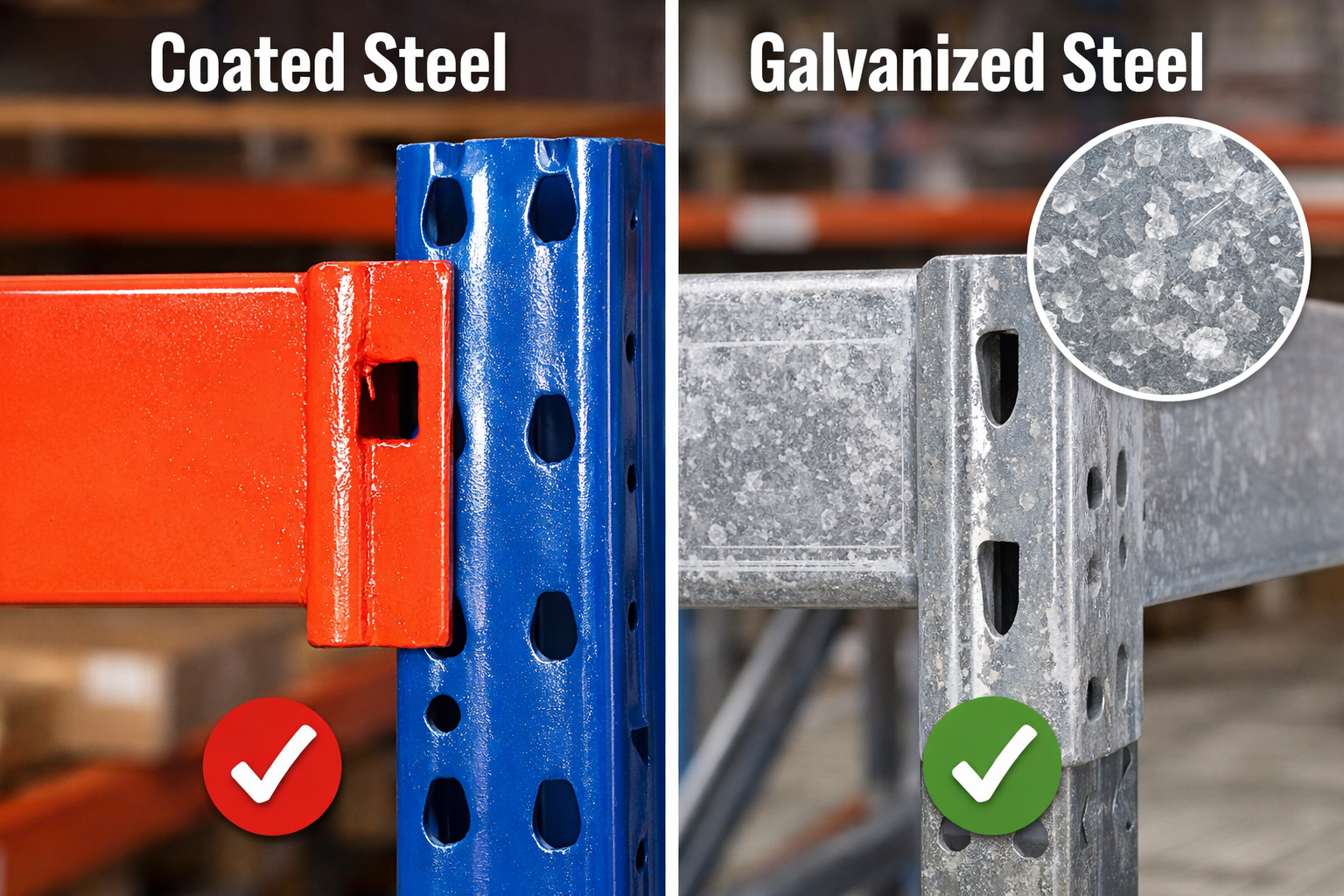

Coated vs galvanized racking is a key consideration for warehouses, cold storage facilities, and industrial shelving environments. The finish applied to steel racking directly affects corrosion resistance, longevity, maintenance needs, and overall lifecycle costs.

As supply chains expand into more demanding environments — including humid regions, coastal zones, and temperature-controlled facilities — choosing the correct steel finish has become a technical and financial decision rather than a cosmetic one. Industry engineers and materials specialists emphasize that finish selection should match environmental exposure, load requirements, and expected service life.

What Is Coated Steel Racking?

Coated racking refers to steel shelving systems that receive a protective surface layer after fabrication. This coating acts as a barrier between the steel and environmental elements that cause corrosion.

Common Coating Types

Several finish options are widely used in storage systems:

- Powder coating: A dry powder applied electrostatically and cured with heat

- Epoxy coatings: Chemical-resistant finishes used in controlled environments

- Polyester coatings: UV-resistant options suitable for indoor and semi-exposed areas

Coatings primarily provide barrier protection, meaning they prevent moisture and oxygen from reaching the steel surface.

Where Coated Racking Is Used

Coated shelving systems are typically installed in:

- Retail stockrooms

- Distribution centers

- Climate-controlled warehouses

- Manufacturing facilities with low humidity

These environments present limited exposure to moisture or corrosive agents, making coated steel a practical solution.

What Is Galvanized Steel Racking?

Galvanized racking uses steel that has been treated with a zinc layer to protect against corrosion. The zinc forms a metallurgical bond with the steel, creating both a barrier and a sacrificial protection system.

Types of Galvanization

Two main galvanizing processes are used in industrial racking:

- Hot-dip galvanizing: Steel is submerged in molten zinc, forming a thick, durable layer

- Pre-galvanized steel: Steel is coated with zinc before fabrication, offering moderate protection

Hot-dip galvanizing provides superior resistance in harsh or outdoor conditions.

Where Galvanized Racking Is Used

Galvanized systems are common in:

- Cold storage and freezer rooms

- Coastal warehouses

- Food processing plants

- Outdoor or semi-exposed storage yards

These settings often involve high humidity, condensation, or corrosive atmospheres.

Coated vs Galvanized Racking: Key Performance Differences

When comparing coated vs galvanized racking, the distinction lies in how each finish protects steel over time.

Corrosion Resistance

| Feature | Coated Racking | Galvanized Racking |

|---|---|---|

| Protection method | Surface barrier | Barrier + sacrificial zinc |

| Performance if scratched | Steel may rust | Zinc continues protecting exposed area |

| Best for | Low-moisture environments | High-moisture or corrosive areas |

Galvanized finishes typically perform better where physical wear or surface damage is likely.

Durability and Lifespan

According to materials engineering references from corrosion research institutes, galvanized coatings generally outlast painted or powder-coated surfaces in wet or chemically active environments.

Coated finishes can last many years indoors but may degrade faster if exposed to abrasion or frequent impacts.

Maintenance Requirements

- Coated systems may require touch-ups if the finish is chipped

- Galvanized systems require less frequent maintenance due to zinc’s self-protecting properties

Lower maintenance demands often make galvanized options more cost-effective over long service periods.

Cost Considerations in Finish Selection

Initial and long-term costs vary between coated and galvanized finishes.

Upfront Cost

Coated racking usually has a lower initial price because the finishing process is faster and uses less material.

Hot-dip galvanized racking often costs more due to:

- Zinc material use

- Additional processing time

- Heavier coating thickness

Lifecycle Cost

Over time, galvanized systems may offer lower total cost of ownership in corrosive settings because they:

- Last longer

- Require fewer repairs

- Reduce replacement frequency

Decision-makers often evaluate both capital expenditure and maintenance budgets when selecting finishes.

Environmental Factors That Influence Finish Choice

Environmental exposure is the leading factor in choosing between coated and galvanized steel.

High-Risk Corrosion Conditions

Galvanized finishes are preferred in environments with:

- Persistent humidity above 70%

- Condensation cycles in cold rooms

- Salt-laden coastal air

- Chemical vapors from industrial processes

Low-Risk Indoor Conditions

Coated finishes perform well in:

- Dry indoor warehouses

- Retail storage areas

- Office or archive shelving

Matching the finish to the environment reduces structural degradation and safety risks.

Industry Standards and Material Guidance

International standards bodies, including ASTM and ISO committees, provide testing methods to measure corrosion performance of coatings and galvanization. These standards help manufacturers verify durability through:

- Salt spray testing

- Humidity chamber testing

- Adhesion and abrasion testing

Such benchmarks support objective comparisons between protective finishes.

What This Means for Storage Planning

Selecting between coated and galvanized steel should align with operational realities.

Key planning considerations include:

- Humidity levels inside the facility

- Temperature fluctuations that cause condensation

- Cleaning practices involving water or chemicals

- Expected lifespan of the installation

Facilities with demanding environmental conditions often benefit from galvanized protection, while controlled indoor operations can use coated systems effectively.

Key Takeaways

- Coated vs galvanized racking differs mainly in corrosion protection methods

- Coated finishes provide barrier protection suited to dry indoor spaces

- Galvanized finishes offer sacrificial zinc protection for harsh environments

- Galvanized systems typically last longer where moisture exposure is frequent

- Lifecycle cost, not just purchase price, should guide finish decisions

FAQs

The main difference lies in corrosion protection. Coated racking uses a surface barrier like powder or epoxy, while galvanized racking has a zinc layer that protects even if scratched. This makes galvanized systems more suitable for high-moisture or corrosive environments.

Galvanized racking generally lasts longer in humid, coastal, or cold storage environments because zinc provides ongoing sacrificial protection. Coated racking can still have a long service life in dry indoor conditions where corrosion risks remain low.

Yes. Cold storage areas often experience condensation and moisture buildup. Galvanized racking resists rust more effectively in these conditions, making it a common choice for freezer rooms, chilled warehouses, and food distribution facilities.

Coated racking may need periodic touch-ups if the finish is chipped or scratched, as exposed steel can rust. In low-impact indoor environments, maintenance needs are minimal, but high-traffic areas may require more frequent inspections.

Engineers evaluate humidity, chemical exposure, temperature variation, and expected lifespan. Budget considerations also matter, but lifecycle cost analysis often shows galvanized systems as more economical in corrosive or moisture-prone environments.