Introduction to Racking Systems

Racking systems are essential components in warehouse storage that optimize space utilization and enhance operational efficiency. These systems come in various configurations, designed to accommodate different types of products and facilitate easy access. The primary purpose of racking systems is to provide a safe and organized method of storing inventory, reducing clutter, and maximizing vertical space in a warehouse environment.

There are multiple types of racking systems available, each catering to specific storage needs. Selective racking is one of the most common types, allowing easy access to individual pallets through a straightforward layout. Drive-in and drive-through racks enable high-density storage by allowing forklifts to enter the racking structure, making them suitable for bulk storage. Meanwhile, cantilever racking is ideal for storing long or irregularly shaped items, such as lumber or piping. Automated racking systems utilize robotics and technology to enhance efficiency, while mezzanine racking integrates elevated storage platforms for additional capacity.

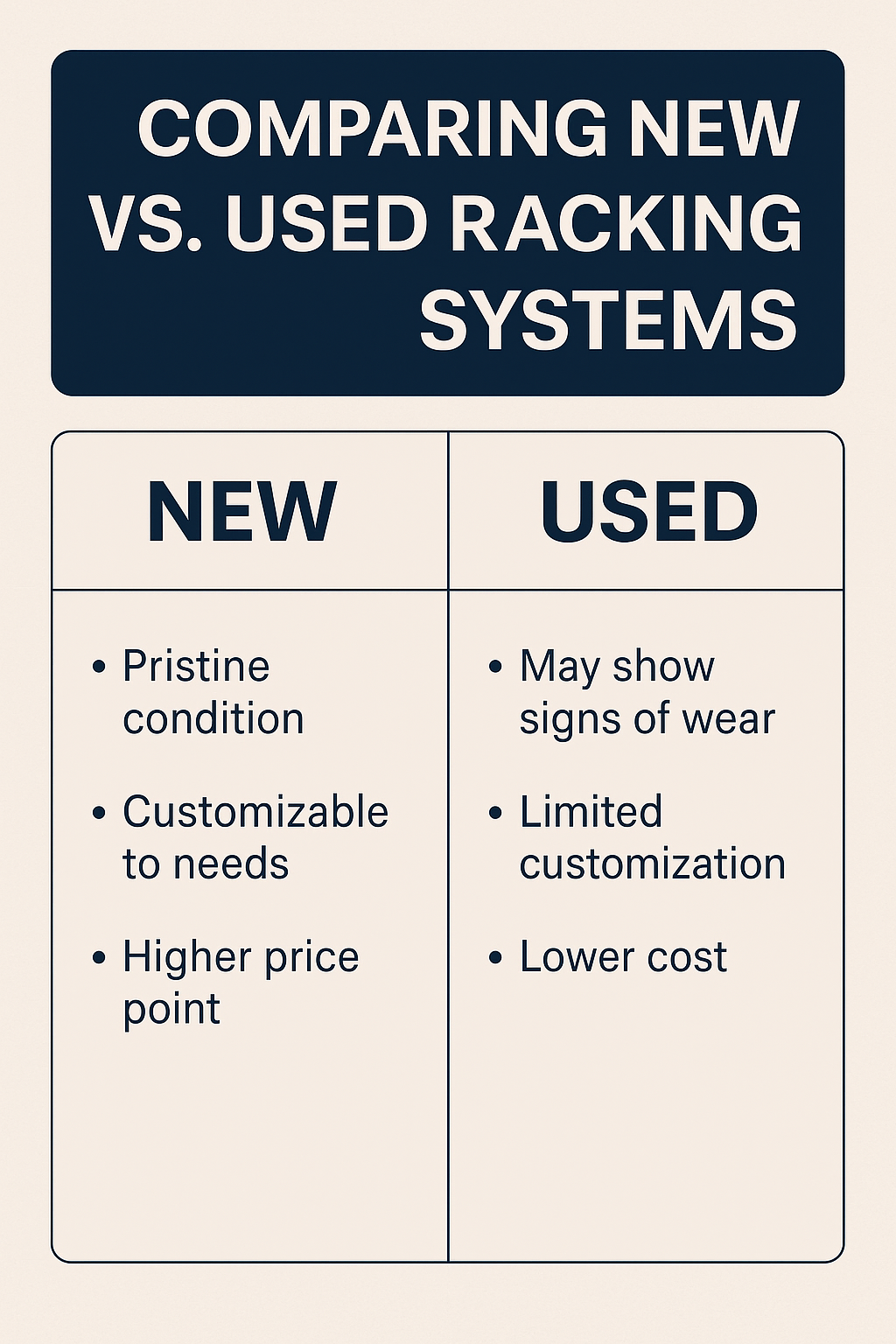

When choosing a racking system, several key factors should be taken into account. These include the type and weight of inventory to be stored, the available warehouse space, and the intended workflow, which affects access and picking efficiency. Additionally, it is crucial to consider safety regulations and compliance standards to ensure the chosen racking system meets industry requirements. A decision between new and used racking systems can significantly impact the financial aspect of this investment; thus, a thorough analysis of costs, longevity, and potential return on investment is vital for making an informed choice.

Understanding the significance of racking systems and their various types allows warehouse managers to select the most suitable options that align with their operational objectives and financial capabilities.

Advantages of New Racking Systems

Investing in new racking systems for your warehouse offers numerous advantages that can significantly enhance operational efficiency and safety. One of the primary benefits of new racking systems is their adherence to the latest safety standards. Manufacturers of new racking systems are required to comply with updated safety regulations, ensuring that the structures are designed to minimize risks and protect both workers and inventory. This adherence not only offers peace of mind but can also prevent costly injuries and damages.

Another salient advantage includes the extended warranties that often accompany new racking systems. Most manufacturers provide substantial warranties, covering structural integrity and performance. This safety net allows businesses to feel secure in their investment, mitigating the long-term risks associated with warehousing equipment. In contrast, used racking systems typically come with limited or no warranties, which can compromise financial security in the event of unforeseen issues.

Customization is a crucial aspect of modern racking systems. New units often come with a variety of customizable options, enabling businesses to precisely tailor their systems according to specific operational needs and space constraints. This level of customization can improve workflow efficiency and maximize space utilization, vital factors in today’s competitive environment.

Moreover, new racking systems incorporate the latest technology features, such as integrated tracking systems and enhanced load management capabilities. These technological advancements facilitate better inventory management, improved space optimization, and streamlined operations. The investment in newer models also often translates to reduced maintenance costs over time, as they are built with more advanced materials and design elements that resist wear and tear.

In summary, opting for new racking systems presents distinct advantages such as improved safety compliance, longer warranties, customization opportunities, and the adoption of cutting-edge technologies. These factors collectively contribute to a more efficient, safe, and ultimately cost-effective warehouse environment. Thus, while the initial investment may be higher, the long-term benefits are substantial and well worth considering.

Advantages of Used Racking Systems

When considering racking systems for a warehouse, one notable option is the use of second-hand or used racking systems. These alternatives provide several advantages that can prove beneficial to warehouse operations, particularly for businesses working within budget constraints. One of the most significant benefits of opting for used racking systems is the cost savings associated with purchasing them. Used racking can often be obtained at a fraction of the price of new systems, allowing businesses to allocate financial resources to other critical areas of their operations.

In addition to the economic benefits, used racking systems typically offer quick availability. Unlike new systems that may require extended lead times for manufacturing and delivery, used racking is often readily available through various suppliers. This immediate access makes it an excellent choice for businesses that require quick solutions, whether for a sudden increase in inventory or the need to optimize warehouse space without delay. Furthermore, many suppliers of used racking systems ensure that their products meet safety and quality standards, thereby providing peace of mind alongside expedited service.

Another significant factor to consider is the eco-friendliness of used racking systems. By choosing to purchase second-hand equipment, businesses can contribute positively to sustainability efforts. This choice not only reduces waste by extending the life cycle of existing products but also minimizes the demand for new materials and the associated carbon footprint linked to manufacturing. In scenarios where an organization requires an efficient racking solution on a tight budget or urgently due to operational needs, used racking systems frequently emerge as the most suitable option.

Costs: New vs. Used Racking Systems

When it comes to selecting racking systems for your warehouse, understanding the financial implications is crucial. The decision to choose between new and used models can significantly affect your overall budget. New racking systems typically come with a higher initial investment, as they are manufactured to current industry standards with the latest technology and materials. These systems are designed to provide optimal safety and efficiency, but the accompanying price tag can be substantial. Pricing for new racking systems can range widely, depending on factors such as size, load capacity, and configuration.

In contrast, used racking systems present a more cost-effective solution. Purchasing pre-owned units can save you a considerable amount of money, as these systems often have a significantly lower purchase cost. However, it’s important to evaluate the condition and compliance of used racking systems prior to purchase. Although they may be less expensive initially, potential hidden costs can arise, such as necessary repairs or modifications to ensure they meet safety regulations and operational requirements.

Installation costs should also be taken into account. New racking systems generally come with manufacturer support, which can simplify the installation process, while used systems could require additional expertise, leading to increased labor costs. Furthermore, ongoing maintenance expenses play a pivotal role in the overall financial assessment. New racking systems may involve lower maintenance costs initially due to their robust construction, yet older systems might necessitate more frequent inspections and repairs, which can accumulate over time.

Evaluating these costs comprehensively allows warehouse managers to make informed decisions that align with their budgets and operational needs, ultimately leading to a more cost-effective warehousing solution.

Safety and Compliance Considerations

When selecting racking systems for warehouses, safety and compliance are paramount. The integrity of storage solutions directly affects warehouse operations, employee safety, and overall productivity. Racking systems must adhere to specific safety standards established by regulatory bodies to ensure their reliability and secure operation. These standards include guidelines on load capacity, structural integrity, and installation methods, which are crucial for preventing accidents and injuries in warehouse environments.

New racking systems are often designed and constructed to meet the latest safety regulations, offering peace of mind to warehouse operators. They typically come equipped with compliance certifications, denoting that they fulfill the necessary standards set by organizations such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). Purchasing a new system ensures that it is built with the latest technology and materials, reducing the likelihood of failure and enhancing overall safety.

Conversely, opting for used racking systems entails certain risks. Older systems may not comply with current safety standards, potentially exposing warehouses to liability in case of an accident. Moreover, used racking systems may suffer from wear and tear that can compromise their structural integrity, leading to significant safety hazards. If these systems have not been adequately maintained or inspected, hidden weaknesses could pose severe risks to personnel and materials alike.

In summary, the choice between new and used racking systems must strongly weigh the implications of safety and compliance. Investing in new systems often provides enhanced safety assurances and better compliance with current regulations, thereby reducing risks associated with outdated or poorly maintained used systems. Therefore, warehouse operators should prioritize safety and compliance when making their selection, ensuring a secure working environment for all employees.

Durability and Longevity: A Comparison

When considering racking systems for a warehouse, durability and longevity are paramount. The choice between new and used racking systems significantly impacts the operational efficiency and safety of a storage facility. New racking systems, typically constructed from high-quality materials, offer enhanced strength and robustness, reducing the likelihood of failure throughout their lifespan. Manufacturers often guarantee a certain period during which the product is expected to perform optimally, providing warehouse managers with a measure of confidence in their investment.

In contrast, used racking systems present a mixed bag when it comes to durability and longevity. Factors such as the age of the racks, prior usage, and maintenance history are critical in assessing their remaining lifespan. While it is possible to find used racks in good condition, wear and tear from previous use may compromise their structural integrity. The material quality of second-hand racks can vary greatly, influencing their performance over time. Therefore, it is essential to evaluate the conditions under which the used racks were stored or utilized to estimate their longevity accurately.

To gauge the remaining lifespan of used racking systems effectively, warehouse operators should conduct thorough inspections, paying attention to signs of damage, rust, or structural deformation. Consulting maintenance logs, if available, can provide insights into the previous maintenance efforts and repairs, further indicating how much usable life remains. Additionally, a trusted dealer can provide valuable advice on the potential risks of purchasing used racks versus the guaranteed durability of new options. Ultimately, understanding these elements will inform a well-rounded decision when selecting racking systems for a warehouse, ensuring operational efficiency and safety in storage practices.

Customization Options and Flexibility

When considering racking systems for warehouses, one of the pivotal aspects that influences decision-making is the level of customization available. New racking systems offer a distinct advantage in this regard, as they can be designed and manufactured to meet specific operational requirements. This includes accommodating unique dimensions, load capacities, and specific storage needs that align with the products being stored. The ability to tailor these systems ensures that organizations can optimize their warehouse space for maximum efficiency and productivity.

For instance, if a warehouse anticipates future growth or diversification of inventory, newly fabricated racking systems can integrate features that support scalability. Brands can work directly with manufacturers to incorporate adjustable shelving, modular designs, or even specialized configurations that cater to both current and anticipated requirements. Such flexibility is essential for businesses aiming to adapt to changing market demands without undergoing significant logistical hurdles.

In contrast, used racking systems often present limitations when it comes to customization. While they can provide a cost-effective solution for businesses, the inherent nature of pre-owned systems means they are typically offered in standard configurations. Modifications may be restricted, and the extent to which these systems can meet specific warehouse needs may vary. Furthermore, older systems may not incorporate the latest design innovations or safety standards, potentially compromising their operational effectiveness.

While both new and used racking systems have their own merits, the flexibility and customization offered by new systems make them an appealing choice for organizations that prioritize tailored solutions. The investment in new systems not only enhances immediate warehouse efficiency but also paves the way for future adaptations that may be necessary as business needs evolve over time.

Assessment and Inspection Tips for Used Racking Systems

When considering the purchase of used racking systems for your warehouse, a thorough assessment and inspection process is crucial for ensuring both safety and functionality. The first step is to evaluate the structural integrity of the racking system. This involves examining all components, including frames, beams, and connectors for any signs of bending, cracking, or deformation. Structural failure in racking systems can lead to catastrophic accidents, so it is essential to prioritize this aspect during the evaluation.

Next, potential buyers should carefully check for signs of rust or corrosion, particularly in metal racking systems. Rust can compromise the durability of the racks and significantly reduce their load-bearing capacity. Look for flaking paint or areas where coatings have worn off, exposing the metal beneath. Additionally, investigate the areas where the racks may come into contact with moisture, as these are often the first places to develop corrosion.

Understanding the history of the used racking system is another vital step in the assessment process. Inquire about the previous usage of the racks, including the types of loads they supported and the environments in which they were used. Racks that have been subjected to heavy stresses or harsh conditions may not be suitable for continued use. Additionally, obtaining maintenance records can provide insight into how well the racks have been cared for over time, giving potential buyers a clearer picture of their overall condition.

Finally, it is advisable to conduct a thorough on-site inspection, if possible. This allows you to get a better sense of the racking system’s physical condition and usability. Ensuring that the used racking system meets industry safety standards and regulatory requirements will ultimately help you make a well-informed purchasing decision.

Conclusion: Choosing the Right Racking System for Your Needs

When selecting an appropriate racking system for your warehouse, it is crucial to evaluate various factors that can impact the effectiveness of your storage solution. As discussed, both new and used racking systems come with their unique advantages and disadvantages. New racking systems offer the latest technology and customization options, while used racking can provide substantial cost savings without a significant compromise on quality, assuming proper inspection and maintenance have been observed.

Cost considerations are paramount for most businesses. Depending on your budget, investing in a new racking system may be justified if it serves your specific storage needs and complies with current safety regulations. On the other hand, acquiring used racking systems can yield substantial financial benefits, allowing for more flexibility in funding other aspects of warehouse operations. However, a thorough assessment of the condition, weight capacities, and safety features of used racking systems is essential to ensure they meet your operational standards.

Furthermore, evaluating durability is another critical aspect. A new racking system may offer warranties and durability guarantees, making it a worthwhile investment for long-term use. Meanwhile, quality used racking can also last for many years if it is sourced from reputable suppliers and has been well-maintained. Customization plays a role in ensuring that your storage solution is tailored to your particular inventory, whether you opt for new or used systems.

In conclusion, the decision between new and used racking systems should be an informed one, taking into account your warehouse’s unique requirements. Each business must weigh their particular circumstances against the advantages offered by both options, ensuring that they select a racking solution which aligns with their operational goals while ensuring safety and efficiency.