Introduction to Pallet Racking and Shelving

In the realm of storage solutions, pallet racking and shelving play crucial roles in optimizing space and enhancing efficiency in various environments, such as warehouses, distribution centers, and retail spaces. While both systems aim to maximize storage capacity, they differ significantly in design, function, and application. Understanding these differences is fundamental for businesses seeking to implement effective storage strategies that align with their operational requirements.

Pallet racking is a robust storage system specifically designed to support heavy loads typically carried on pallets. This type of racking is ideal for businesses that need to store bulk items, heavy machinery, or packaged goods. The modular structure of pallet racking allows for flexible configurations, making it suitable for varying product sizes and weights. Common types of pallet racking include selective racking, drive-in racking, and pallet flow racking, each catering to different storage needs and accessibility preferences.

On the other hand, shelving primarily focuses on smaller, individual items or products that do not require full pallet support. Shelving units are versatile and come in various sizes and designs, making them perfect for retail environments, offices, and small warehouses. They can accommodate an array of goods, from documents and tools to consumer products. Unlike pallet racking, shelving is typically not designed to handle significant weight, prioritizing a more organized display of products and easy access.

Prior to choosing between pallet racking and shelving, it is essential for businesses to evaluate their specific storage requirements. Factors such as the nature of the inventory, load capacities, and accessibility should be considered to determine which system will best serve their operational needs. As we explore the unique features and benefits of each system, a clearer understanding of their applications will emerge, guiding businesses in making informed storage decisions.

Definition of Pallet Racking

Pallet racking is a storage system specifically designed to hold and organize pallets, which are flat transport structures that facilitate the handling of goods and materials. This type of storage solution is usually found in warehouses, distribution centers, and retail operations where there is a need to store large volumes of products in a systematic and space-efficient manner. The primary advantage of pallet racking lies in its ability to maximize vertical space, thereby optimizing the overall storage capacity of a facility.

The structure of pallet racking typically consists of vertical frames and horizontal beams, forming a robust skeleton capable of supporting heavy loads. The frames are often constructed from steel, providing durability and strength, while beams can be configured at various heights to accommodate differing pallet sizes. There are several types of pallet racking systems, each tailored for specific needs. For example, selective pallet racking, which allows direct access to each pallet, is versatile but may consume more floor space. In contrast, drive-in and drive-thru racking systems enable high-density storage and quick access to products at the back of the rack.

Common applications of pallet racking are prevalent in environments dealing with bulk inventory, such as food distribution centers, manufacturing facilities, and e-commerce warehouses. These systems are designed to increase operational efficiency by facilitating easy picking and storage processes. Additionally, pallet racking provides enhanced organization and inventory tracking capabilities, further contributing to effective warehouse management. The modular nature of these systems allows for easy scalability to adapt to changing inventory requirements, making them an ideal choice for businesses aiming to optimize their storage solutions.

Definition of Shelving

Shelving refers to a system of horizontal surfaces, typically made from wood, metal, or plastic, that are used to store various items in an organized manner. This storage solution is prevalent across multiple environments, including homes, retail stores, and industrial settings. The primary purpose of shelving is to provide a means to display, access, and store products efficiently. Unlike pallet racking, which is designed to handle larger, heavier loads, shelving is specifically tailored for smaller or lighter items, making it an ideal choice for diverse applications.

There are several types of shelving systems, each catering to different needs. Industrial shelving is commonly used in warehouses and manufacturing facilities. This type is designed for strength and durability, ensuring that it can support various tools, parts, and materials. Retail shelving, on the other hand, focuses on attractiveness and usability, enabling businesses to display products in a manner that is both aesthetically pleasing and easy for customers to navigate. This type is often more customizable, allowing retailers to adapt the heights and widths according to product dimensions.

Home shelving is another popular category that encompasses a variety of styles, including bookcases, cabinets, and floating shelves. These options allow homeowners to maximize space and keep belongings organized while also enhancing the interior design of their living spaces. Shelving systems can be adjusted to accommodate changing storage needs, providing versatility that pallet racking cannot offer. Overall, shelving serves as a practical, efficient, and versatile storage solution suited for various environments, particularly where the storage of lighter or smaller items is paramount.

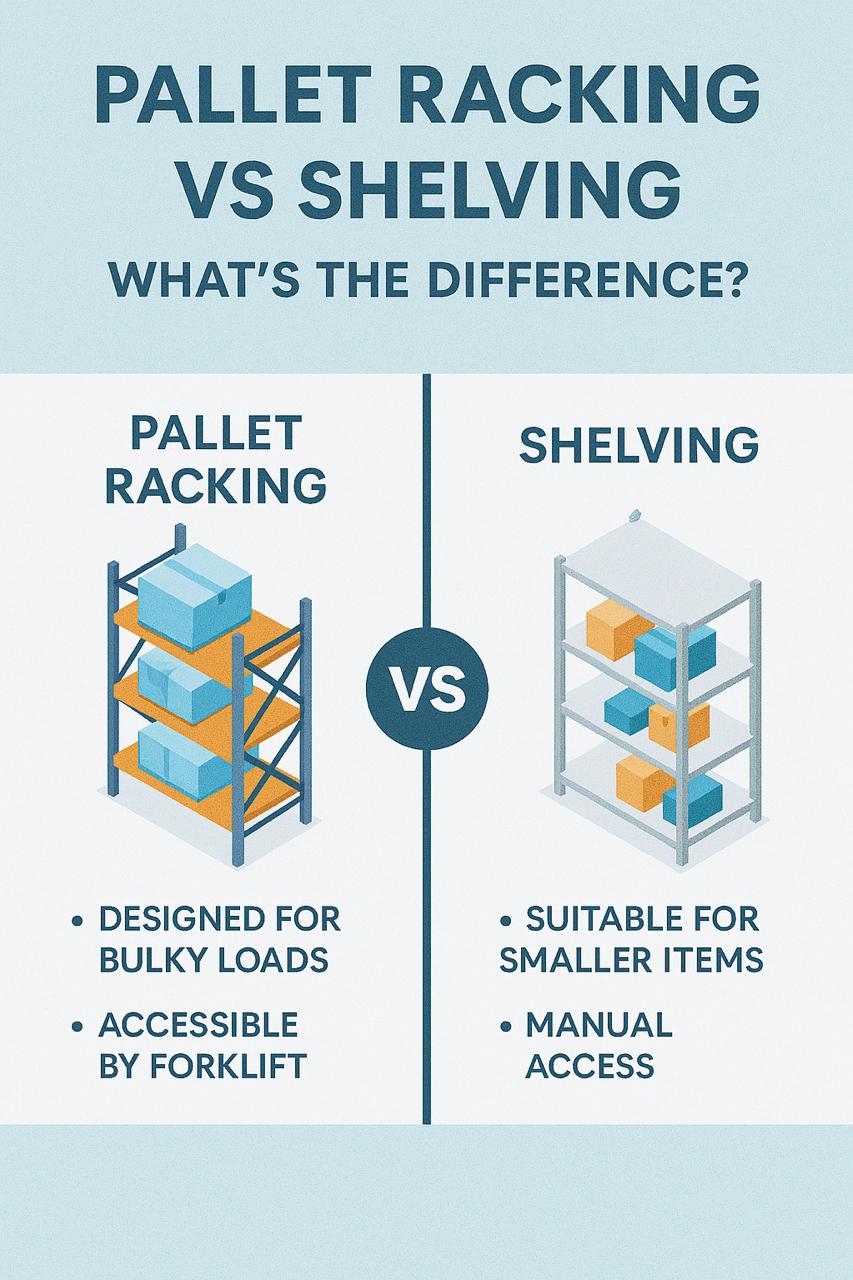

Key Differences Between Pallet Racking and Shelving

Pallet racking and shelving serve as essential storage solutions across various industries, yet their applications and specifications differ significantly. Understanding these differences is crucial for businesses in selecting the right storage system to meet their unique needs.

One of the most notable differences lies in weight capacity. Pallet racking is designed to support heavier loads, accommodating substantial items often found in warehouses, manufacturing facilities, or distribution centers. These systems can handle weights ranging from a few hundred to several thousand pounds per shelf. Conversely, shelving units are typically constructed to hold lighter items, making them ideal for retail environments or offices where products such as books or small boxes are stored.

In terms of construction materials, pallet racking is commonly made from robust steel, providing durability and strength required for substantial loads. Shelving units, on the other hand, can be manufactured from various materials, including wood, metal, or plastic, depending on the intended use and load-bearing requirements. This diversity allows for a wider range of aesthetic and functional choices for consumers.

The design of pallet racking systems is generally more complex, allowing for vertical stacking and creating several rows and columns to maximize storage space efficiently. Shelf heights can be adjusted to fit different pallet sizes. In contrast, shelving systems often follow a simpler design, featuring fixed or adjustable shelves that suit specific storage needs but may not leverage vertical space as effectively.

Finally, accessibility plays a critical role in distinguishing these two storage systems. Pallet racking often requires specialized equipment, such as forklifts, for loading and unloading, which may limit ease of access. Shelving, meanwhile, allows for simpler manual access to items, making it more user-friendly for lighter goods. Understanding these key differences between pallet racking and shelving can assist organizations in making informed decisions based on their storage challenges.

Advantages of Pallet Racking

Pallet racking has emerged as a preferred storage solution in various industrial and commercial settings due to its numerous advantages. One of the primary benefits of pallet racking is the substantial increase in storage density it provides. By utilizing vertical space effectively, pallet racking systems allow businesses to store a greater volume of products in a confined area, optimizing warehouse footprint and significantly enhancing productivity.

Another noteworthy advantage of pallet racking is its versatility in accommodating a diverse range of products. Whether a facility needs to store bulk items, small packages, or specific goods that require distinct handling, pallet racking can be configured to suit these varying needs. This adaptability ensures that businesses can maximize their storage capacities without compromising on accessibility or safety.

Improved accessibility for forklifts and pallet jacks is also a key feature of pallet racking systems. Unlike traditional shelving units, which often limit maneuverability, pallet racking allows for easy access to stored goods. Aisles can be designed to accommodate the specific dimensions of the handling equipment used, further streamlining operational processes. For instance, narrow aisle pallet racking systems are ideal for facilities where space is at a premium, allowing for more efficient inventory management.

Furthermore, pallet racking systems can be tailored to meet the unique requirements of various industries. For example, cold storage facilities benefit immensely from the utilization of pallet racking, as it allows for effective organization of perishable goods while maintaining optimal temperature conditions. Similarly, manufacturing operations can leverage pallet racking for efficient management of raw materials and finished products. Ultimately, these advantages make pallet racking an indispensable solution for businesses aiming to enhance their storage efficiency and adaptability.

Advantages of Shelving

Shelving is an essential component of inventory management and organization in various industries, providing numerous advantages that make it a preferred choice for many businesses. One of the primary benefits of shelving is its versatility. Depending on the design, shelves can accommodate a variety of items, ranging from small components and documents to larger products. This adaptability allows companies to customize their storage solutions to meet specific needs, whether in retail environments, warehouses, or offices.

Another significant advantage of shelving is its lower cost compared to pallet racking systems. Generally, shelving requires less material and engineering complexity, which often results in lower initial investment and installation costs. This affordability makes it a viable option for small businesses and startups that may not have the budget for elaborate pallet racking systems. Additionally, the ongoing maintenance and operational costs associated with shelving are often lower, further boosting its appeal for businesses focused on cost efficiency.

Moreover, shelving is particularly well-suited for storing small items and components, which are commonly found in settings such as retail stores, libraries, and manufacturing facilities. In retail, for example, shelving displays products in an organized manner that enhances visibility and accessibility for customers. In warehouses, modular shelving can efficiently store various components, allowing workers to quickly locate and retrieve items during fulfillment processes. Similarly, libraries utilize shelving to systematically organize books and materials, creating an efficient flow for both staff and patrons.

In conclusion, shelving offers distinct benefits, including its versatility, cost-effectiveness, and suitability for small items, making it a practical storage solution for diverse industries and environments. Understanding these advantages can help businesses make informed decisions regarding their storage options, ultimately enhancing operational efficiency.

Selecting the Right System for Your Needs

Choosing between pallet racking and shelving systems is a fundamental decision that can significantly impact the efficiency and productivity of your storage operations. This selection process should be based on multiple factors, including available space, type of inventory, operational processes, and budget constraints.

First and foremost, assess the space in your facility. Pallet racking systems are suitable for larger spaces and are designed to accommodate bulk storage, making them ideal for warehouses with high ceilings and ample floor area. Conversely, shelving is better suited for smaller spaces and offers flexibility for various configurations, particularly in retail or office environments where accessibility is crucial.

Next, consider the type of inventory being stored. If your business handles large items or pallets, a pallet racking system will likely be more beneficial due to its higher weight capacity and ability to handle oversized products. In contrast, if your inventory consists of smaller items or requires frequent picking, shelving might be more appropriate, as it facilitates better organization and quick access.

Operational processes are another key indicator. Evaluate your workflow—if you require frequent access to various items, a shelving system can simplify the picking process, while pallet racking is advantageous for operations that prioritize bulk movement. Furthermore, budget considerations play a critical role; pallet racking systems often involve a higher initial investment while offering durability and longevity, whereas shelving systems can be more economical upfront but may require replacements or upgrades over time.

Lastly, assess your unique business needs. Analyzing current workflows and future growth potential can guide your choice effectively. By considering these factors, businesses can strategically select a storage solution that aligns with their operational requirements, ultimately enhancing productivity.

Safety Considerations and Compliance

When it comes to storage solutions, safety is of paramount importance, particularly in environments where pallet racking and shelving systems are utilized. Understanding the safety considerations for both systems can help mitigate risks and ensure a compliant workspace. First and foremost, it is essential to adhere to local regulations and industry standards. Many countries have established guidelines that dictate the design, installation, and maintenance of these storage systems. Compliance with these regulations not only protects employees but also minimizes liability for businesses.

One of the critical safety concerns with pallet racking systems is the weight distribution and load capacity. It is vital that the pallets are not overloaded beyond their specified capacity to prevent collapses, which can lead to serious injuries. Regular inspections should be conducted to identify any signs of wear or damage to the racking structure. Workers should be trained to recognize safety hazards and ensure that all items are stored properly. This includes ensuring that loads are balanced and securely placed to avoid shifting during retrieval.

On the other hand, shelving systems often encounter different safety challenges, particularly in accessibility. Shelving should be designed for ergonomic access, minimizing the need for employees to reach awkwardly or use improper lifting techniques. Proper signage indicating load limits should be visibly placed on shelving units to inform users of safe practices. Further, deploying safety features such as safety pins, anti-tip devices, and proper anchor systems can significantly enhance the stability of both shelving and racking solutions.

In summary, safety considerations for pallet racking and shelving systems are critical for operational efficiency. Compliance with applicable guidelines, combined with best practices for installation and maintenance, ensures that these storage solutions uphold a safe working environment. By prioritizing safety, businesses can effectively reduce accidents and foster a culture of compliance within the workplace.

Conclusion

In summary, understanding the distinction between pallet racking and shelving is essential for making informed decisions regarding your storage needs. Both solutions have unique advantages and are better suited for different types of products and environments. Pallet racking systems are designed to support large quantities and heavy loads, making them ideal for warehouses and distribution centers. They provide excellent vertical space utilization and can accommodate various pallet sizes, thereby enhancing accessibility and efficiency in inventory management.

On the other hand, shelving units offer versatility and adaptability for different environments, including retail stores and offices. They are typically intended for smaller items or products that require quick access, and can be configured in numerous ways to suit specific requirements. Shelving systems can vary widely in design and functionality, allowing businesses to maximize their storage space while maintaining an organized layout.

Choosing between pallet racking and shelving ultimately depends on your individual storage demands, the nature of your inventory, and the available floor space. It is crucial to consider factors such as load capacity, accessibility, and the layout of your storage area. By thoroughly evaluating both options, businesses can optimize their storage solutions, reduce costs, and improve operational efficiency. As storage needs evolve, revisiting this evaluation regularly will ensure that the chosen system continues to meet the demands of an ever-changing inventory landscape.