Introduction to Picking Accuracy

Picking accuracy is a critical metric in warehouse operations, reflecting the precision with which items are selected and prepared for distribution. It pertains to the correctness of the items picked in a given order relative to what was intended by the customer or the ordering system. A high level of picking accuracy ensures that the right products are delivered to the right customers, thus minimizing errors that may lead to order discrepancies.

The importance of picking accuracy cannot be overstated, as it has a direct impact on various facets of warehousing, notably order fulfillment and customer satisfaction. When picking accuracy rates are elevated, the likelihood of successful order completion increases, leading to timely and accurate deliveries. This contributes to higher customer retention and satisfaction rates, as customers tend to favor organizations that consistently meet their expectations regarding order accuracy. Conversely, low picking accuracy can result in incorrect items being shipped, which can cause delays, increase return rates, and ultimately harm a company’s reputation.

In addition to influencing customer satisfaction, picking accuracy enhances overall operational efficiency within a warehouse. Accurate picking minimizes the need for rework or adjustments, thus reducing labor costs and the time spent on each order. Efficient use of labor and resources can lead to improved productivity, allowing businesses to handle larger volumes of orders without compromising on accuracy. As operational efficiency improves, so too does profitability, creating a favorable cycle that benefits the entire organization.

By understanding the significance of picking accuracy, one can appreciate the subsequent sections that will delve into the role of racking systems in enhancing this crucial aspect of warehouse management. Racking solutions are designed not only to optimize storage space but also to contribute to improved picking processes, thereby positively affecting accuracy rates.

Understanding Racking Systems

Racking systems play a crucial role in the efficiency of warehouse operations, significantly impacting picking accuracy. Various types of racking systems are utilized in warehouses, each designed with specific functionalities that cater to different storage requirements. Understanding these systems is essential for optimizing inventory management and enhancing picking processes.

Selective racking is one of the most common types of racking used in warehouses. This system consists of upright frames and horizontal beams, allowing easy access to each pallet. Selective racks are versatile and ideal for a variety of products, offering excellent visibility and picking efficiency. As items can be picked from the front of the rack, they facilitate fast order fulfillment, making them particularly beneficial in environments with high turnover rates.

Drive-in racking systems provide a compact, space-efficient way to store large quantities of homogenous products. Items are loaded from one side and retrieved from the same point, making it a Last In, First Out (LIFO) system. This design minimizes aisles and maximizes storage density; however, it can increase challenges concerning picking accuracy, as items deeper in the rack may become less accessible.

Push-back racking is another innovative solution that combines storage density with accessibility. This system utilizes a series of carts that move back along rails when pallets are loaded. When a new pallet is placed, it pushes the existing pallets back, which allows for a streamlined picking process while retaining the benefits of high storage capacity. This type is particularly suited to warehouses that experience high volumes of mixed-item picking.

Pallet flow racks are designed for high-volume operations as well, featuring a lane system that utilizes gravity to move pallets from the back of the rack to the front. This mechanism supports the First In, First Out (FIFO) method, which is advantageous for products with expiration dates, ensuring that older inventory is picked first. The design facilitates efficient order fulfillment while maintaining inventory rotation.

Overall, understanding these various racking systems, such as selective, drive-in, push-back, and pallet flow racks, is vital for warehouse managers aiming to enhance picking accuracy. By selecting the appropriate racking system, warehouses can improve their operational efficiency and better meet the demands of their logistics and fulfillment processes.

The Connection Between Racking and Picking Processes

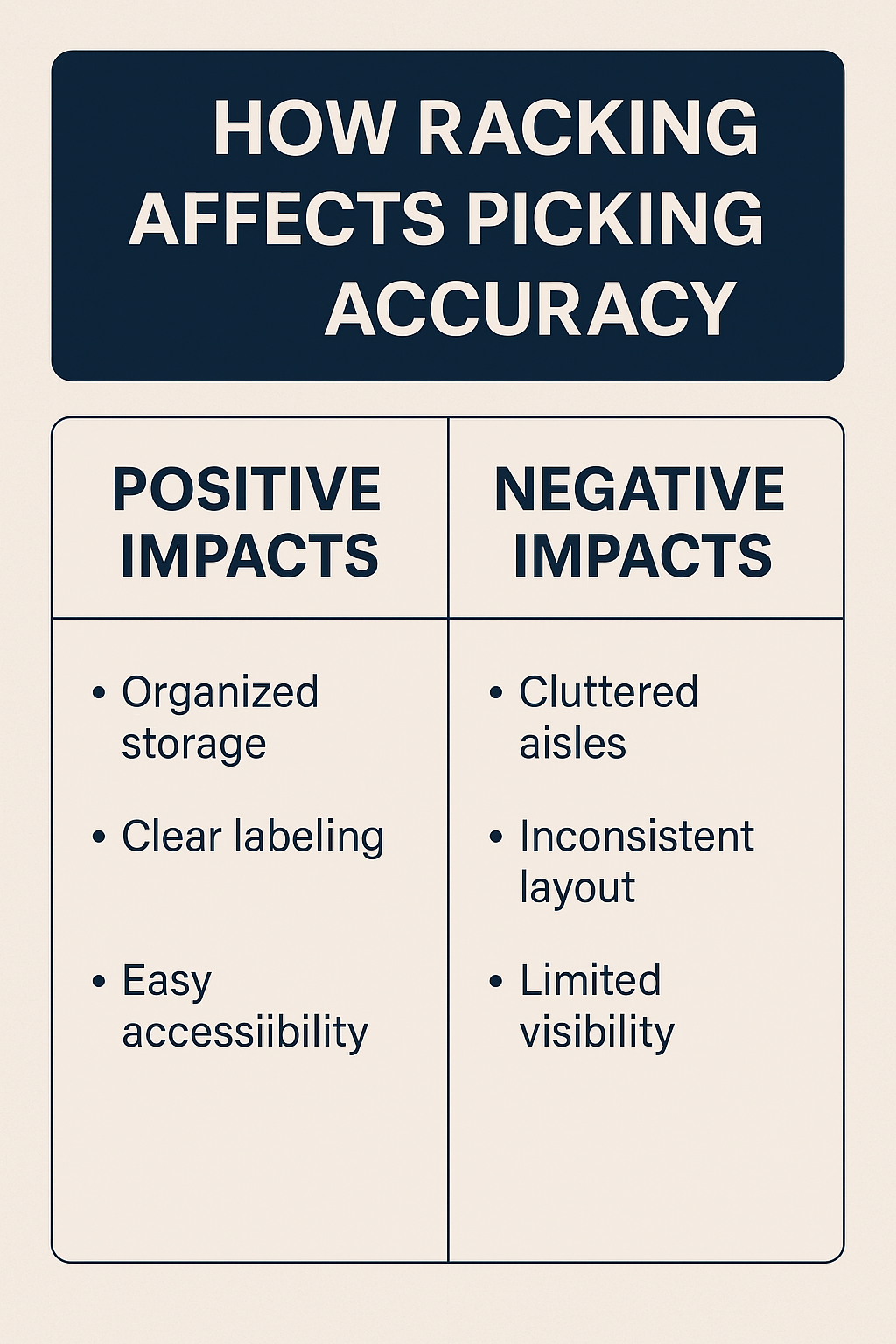

The effectiveness of warehousing operations is heavily influenced by the type of racking systems used. Racking designs play a critical role in shaping the picking processes that warehouses implement. When strategically designed, racking can enhance the efficiency and accuracy of picking operations, while poorly designed systems can introduce complexities that hinder productivity.

Different racking configurations, such as selective, drive-in, and push-back racking, cater to various storage needs and impact the flow of goods. Selective racking, for instance, allows for easy access to stored items, facilitating a smoother picking process. This configuration can significantly reduce the time it takes to retrieve products, thus improving picking accuracy. Conversely, drive-in racking systems, while maximizing storage density, can complicate retrieval efforts, requiring more time for picking and potentially leading to errors.

The flow of goods in relation to these racking systems is essential for optimizing warehouse operations. A well-organized racking layout promotes a logical flow of inventory, enabling efficient movement of pickers through the storage area. When the layout aligns with the frequency of item retrieval—commonly referred to as the ABC analysis—picking accuracy improves further. High-frequency items can be placed in easily accessible locations, thereby reducing travel time and the likelihood of mistakes during the picking process.

Furthermore, integrating technology into racking systems can facilitate real-time inventory tracking, which enhances picking accuracy. Automated storage and retrieval systems (AS/RS) can significantly streamline picking operations by minimizing human error and optimizing the organization of storage units. Overall, the design and implementation of racking systems directly influence picking operations, demonstrating their importance in achieving high levels of accuracy and efficiency in warehousing environments.

Common Challenges in Picking Accuracy Related to Racking

In the realm of warehousing, the design and arrangement of racking systems play a crucial role in determining picking accuracy. However, several challenges can arise when these systems are not optimized for the task at hand. One prevalent issue is poor item visibility. When items are not clearly visible, workers may struggle to locate the required SKUs quickly, resulting in delays and an increased likelihood of picking errors. This challenge is particularly pronounced in warehouses with high shelving units where items can become obscured from sight, leading to mispicks or unnecessary time spent searching.

Another significant concern is the overcrowding of SKUs within storage locations. This often occurs when warehouses require high-density storage without adequate consideration for item turnover rates. Overloaded shelves can lead to items being obscured, making it difficult for pickers to retrieve the correct product promptly. Furthermore, overcrowded racking may encourage haphazard item placement, exacerbating picking difficulties and increasing the risk of errors in fulfilling orders.

Navigational challenges within the racking system also contribute substantially to picking inaccuracies. Designs that do not facilitate easy access can result in workers maneuvering through tight aisles or navigating around obstructions. In such environments, pickers may resort to shortcuts that can lead to mistakes, such as selecting the wrong item or omitting necessary SKUs entirely. In addition, complex layouts can cause confusion, disorienting staff and prolonging the time taken to complete orders.

Ultimately, these challenges highlight the importance of optimizing racking systems to enhance picking accuracy. Addressing issues regarding visibility, SKU overcrowding, and navigation can significantly reduce the occurrence of picking errors, thereby improving overall operational efficiency in the warehouse.

Best Practices for Racking Design to Enhance Picking Accuracy

Designing an effective racking system is crucial for enhancing picking accuracy in warehouses. One of the first best practices involves optimal Stock Keeping Unit (SKU) placement. This requires a strategic arrangement of inventory based on factors such as item velocity and size. Fast-moving items should be located closer to packing and shipping areas, minimizing travel distance for pickers and thereby reducing the likelihood of errors. Additionally, organizing SKUs in a manner that clusters similar items can streamline the picking process. By placing frequently picked items at eye level, one can further boost accuracy and efficiency.

Another critical consideration is ergonomic design. Racking systems should be tailored to accommodate the physical demands of the workforce. Incorporating adjustable shelving and utilizing storage solutions that reduce reaching and bending can significantly lower the risk of picking errors. When employees can operate in a more comfortable and efficient manner, their focus and execution improve, leading to enhanced picking accuracy. Training employees on best practices related to using ergonomically friendly racking systems can further cement these advantages.

The integration of technology plays an increasingly vital role in establishing best practices for racking design as well. Automated inventory management systems and barcode scanning technologies can drastically reduce human error by ensuring accurate tracking of stock. Systems that provide real-time data on inventory levels can optimize racking setups by highlighting which items require repositioning or replenishing. This ensures that pickers always have access to the correct items at the right time, further reducing inaccuracies in the picking process. By employing a combination of intelligent SKU placement, ergonomic considerations, and technological innovations, warehouses can greatly enhance picking accuracy and overall operational efficiency.

Role of Technology in Racking Systems and Picking Accuracy

The integration of technology in warehousing plays a significant role in enhancing the effectiveness of racking systems, particularly in relation to picking accuracy. Modern warehouse management systems (WMS) provide real-time data and analytics, which enable warehouse operators to optimize their racking layouts effectively. By analyzing inventory levels, customer demand, and other key performance indicators, a WMS can assist in slotting decisions that place high-rotation items in easily accessible racking locations. This, in turn, reduces the time spent during picking processes and increases overall accuracy.

Additionally, automated picking solutions such as robotic picking systems and conveyor belts have revolutionized the warehousing landscape. These technologies work seamlessly with racking systems to collect and sort items with precise accuracy. For example, robots equipped with advanced sensors can navigate through warehouse aisles to retrieve products directly from the racks, significantly reducing human errors associated with manual picking. Furthermore, these automated solutions are often designed to function in conjunction with various racking configurations, allowing for an adaptive approach that caters to different operational needs.

Moreover, innovations such as voice-directed picking and wearable technology have emerged to bridge the gap between human workers and their technological counterparts. Voice-guided systems provide real-time instructions directly to warehouse staff, ensuring that items are picked from the correct locations in the racking system. These systems not only enhance picking accuracy but also allow workers to maintain a higher level of productivity. The synergy created by integrating technology with racking systems ensures that both static and dynamic storage solutions are utilized to their fullest potential, directly influencing the efficiency and accuracy of picking operations.

Case Studies of Successful Implementation of Racking Solutions

In the contemporary warehousing landscape, the importance of picking accuracy cannot be overstated. Case studies from leading companies demonstrate how optimized racking systems can significantly enhance this aspect of operations. One pertinent example is a major retail giant that revamped its warehouse layout by integrating a dynamic racking system tailored to its high-volume picking processes. Prior to this implementation, the company experienced frequent picking errors, resulting in increased operational costs and customer dissatisfaction. By adopting a selective racking solution, they improved product accessibility and reduced the time spent searching for items. The outcome was a remarkable 30% increase in picking accuracy, ultimately boosting customer satisfaction and sales.

Another notable case is a manufacturer of electronic goods that transitioned to a multi-tier racking system. This new approach allowed them to maximize vertical space while ensuring easy access to products. During the implementation phase, the company confronted various challenges, including employee training and initial resistance to change. However, by engaging workers in the design process and emphasizing the benefits of the new system, they successfully mitigated these concerns. The end result was a 25% reduction in the time taken to complete order picking, coupled with a significant drop in inventory errors.

Additionally, a food distribution company implemented a drive-in racking solution to optimize its cold storage facilities. This was particularly essential for maintaining the integrity of perishable items. The transition faced hurdles, such as adapting existing processes to accommodate the more compact storage method. However, post-implementation analysis revealed that order accuracy improved by 40%, which was imperative for meeting compliance standards in the industry. Through these varied examples, it becomes clear that strategic racking solutions directly contribute to enhanced picking accuracy, increased efficiency, and overall improved operational performance in warehousing.

Future Trends in Racking Systems and Picking Accuracy

The evolution of racking systems continues to play a pivotal role in enhancing picking accuracy within warehouse operations. As technology advances, several future trends are poised to further transform the landscape of warehousing.

One notable trend is the shift towards modular racking systems. These systems offer remarkable flexibility allowing for quick reconfiguration according to changing inventory needs. Unlike traditional racking options, modular systems can be easily adjusted, enabling warehouses to optimize space utilization and improve picking processes. This adaptability can significantly enhance picking accuracy, as workers can more easily locate items based on their immediate availability in the system.

Additionally, the incorporation of advanced materials in racking design stands to impact picking efficiency. Lightweight yet robust materials can reduce the overall weight of racking systems, making them easier to handle and modify. These materials can contribute to the reduction of structural strain under heavy loads, ultimately fostering an environment wherein picking tasks can be performed rapidly without compromising safety or accuracy.

Furthermore, the integration of automation is reshaping the future of racking systems. Automated storage and retrieval systems (AS/RS) can minimize human error by employing robotics to handle inventory. Such systems not only enhance accuracy but also speed up fulfillment rates. As machine learning algorithms become integrated into warehouse management systems, predictive analytics may facilitate instantaneous restocking or retrieval decisions. This predictive capacity could lead to an unprecedented level of order fulfillment accuracy.

Looking ahead, the synergy between modular designs, innovative materials, and automation will likely redefine how warehouses operate. By embracing these trends, facilities can significantly bolster their picking accuracy, thereby improving overall operational efficiency. The focus on these advancements indicates a clear trajectory towards an increasingly proficient warehouse system in the future.

Conclusion and Recommendations

In conclusion, the role of racking systems in enhancing picking accuracy within warehouse operations cannot be understated. The optimization of these systems directly correlates with operational efficiency, affecting everything from inventory management to order fulfillment accuracy. Throughout this discussion, we have examined the various types of racking solutions and their impact on picking processes, noting that a well-structured racking layout minimizes errors and streamlines workflows.

Warehouse managers are encouraged to carefully evaluate their current racking systems. Factors such as the type of goods stored, picking methods employed, and the layout of the warehouse should guide decisions regarding racking configurations. A dynamic approach towards racking design is imperative; adjustments should be made based on ongoing assessments of warehouse performance metrics. Regular evaluations can pinpoint areas for improvement and lead to design modifications that enhance picking accuracy.

Additionally, investing in technology can significantly augment the effectiveness of existing racking systems. Automated systems, such as pick-to-light or warehouse management software, when integrated with traditional racking setups, can provide real-time data to optimize picking routes and reduce errors. Training staff on best practices is also essential; knowledgeable employees are crucial for maximizing the potential of both the racking systems and automated technologies.

Ultimately, the success of any warehousing operation hinges on a harmonious balance between efficient racking design and a commitment to continuous improvement. By adopting a proactive strategy and implementing tailored solutions, warehouse managers can significantly uplift the picking accuracy of their facilities, thereby enhancing overall operational effectiveness and customer satisfaction.